|

Getting your Trinity Audio player ready...

|

Conduit bending is a daily reality for electricians, especially in commercial and industrial settings where branch conduit installations are common. From racks of EMT to runs of RMC, the demands on accuracy, consistency, and speed are high, and the physical strain can be even higher.

That’s why Milwaukee has introduced the M18 FUEL Branch Conduit Bender w/ AUTO-ZERO (5150-20). Unlike traditional hand benders that are fatiguing and inconsistent or bulky powered units that require a 20A outlet, this cordless solution delivers accuracy, portability, and productivity right at the point of install.

Here are the 10 reasons electricians need this tool in their arsenal.

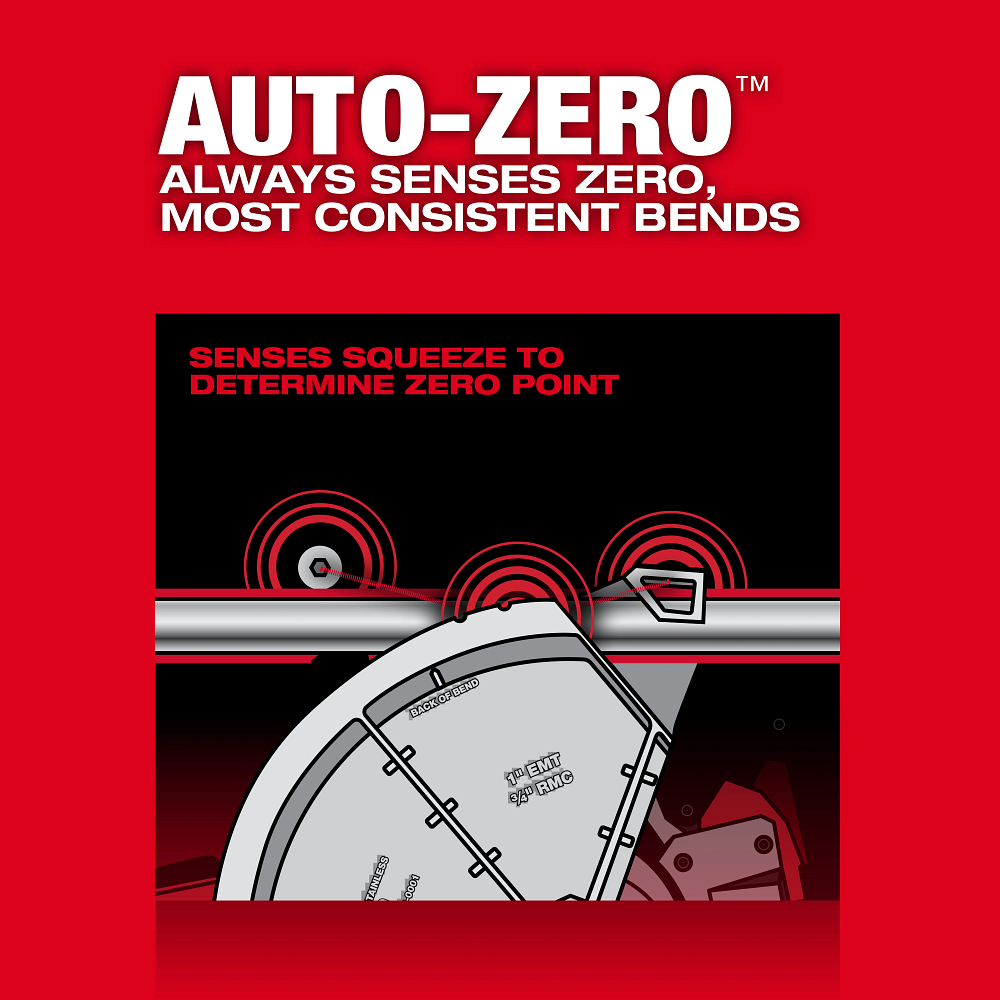

1. Consistent Bends Every Time

Manual bending often means “guess and check,” leading to wasted conduit and costly rework. The AUTO-ZERO, feature on Milwaukee’s bender senses 0° before every bend, then automatically stops at the programmed target angle. That means repeatable, reliable results without constant tweaking.

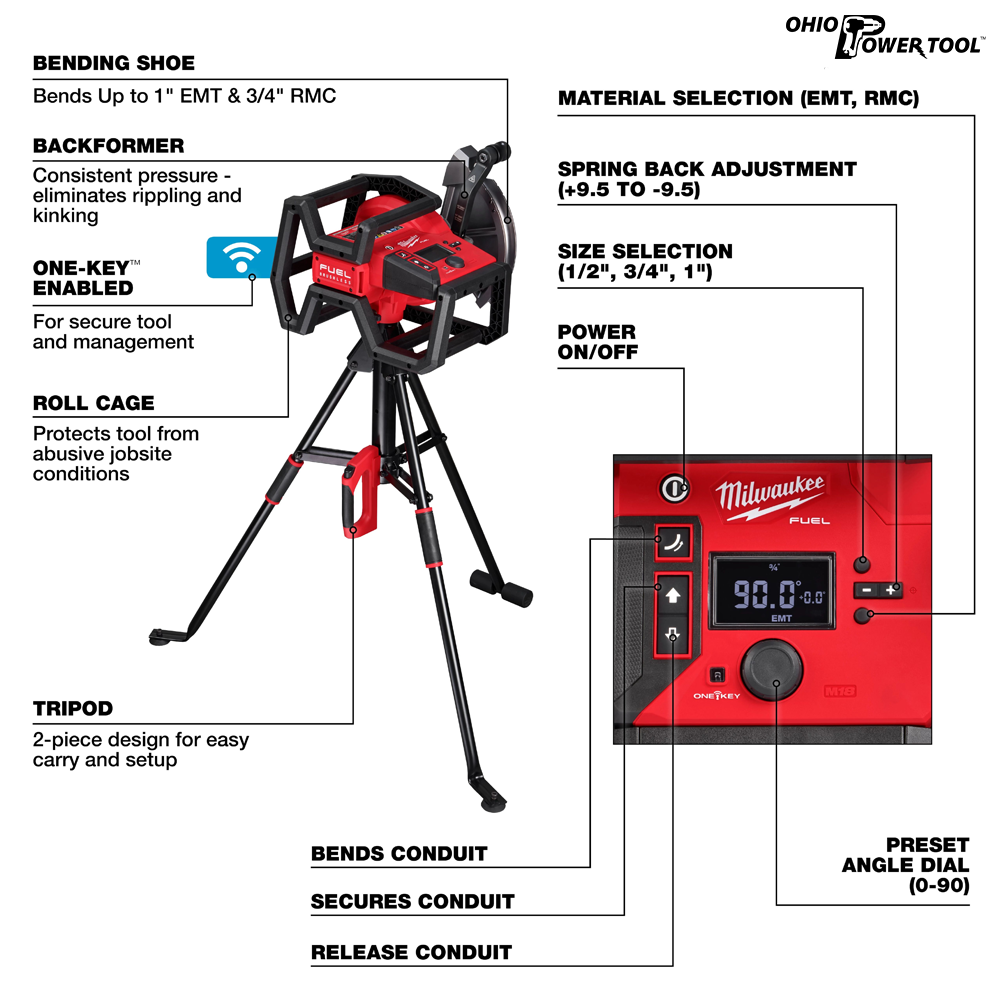

2. Built-In Digital Springback Chart

Printed springback stickers wear out, get lost, and don’t account for batch-to-batch variation. Milwaukee solves this with a digital springback system that includes:

Default offsets for EMT and RMC.

Programmable adjustments in ±0.5° increments.

Memory that stores settings for all sizes, materials, and angles.

No more scrap, wasted conduit, or lost notes, just precision every time.

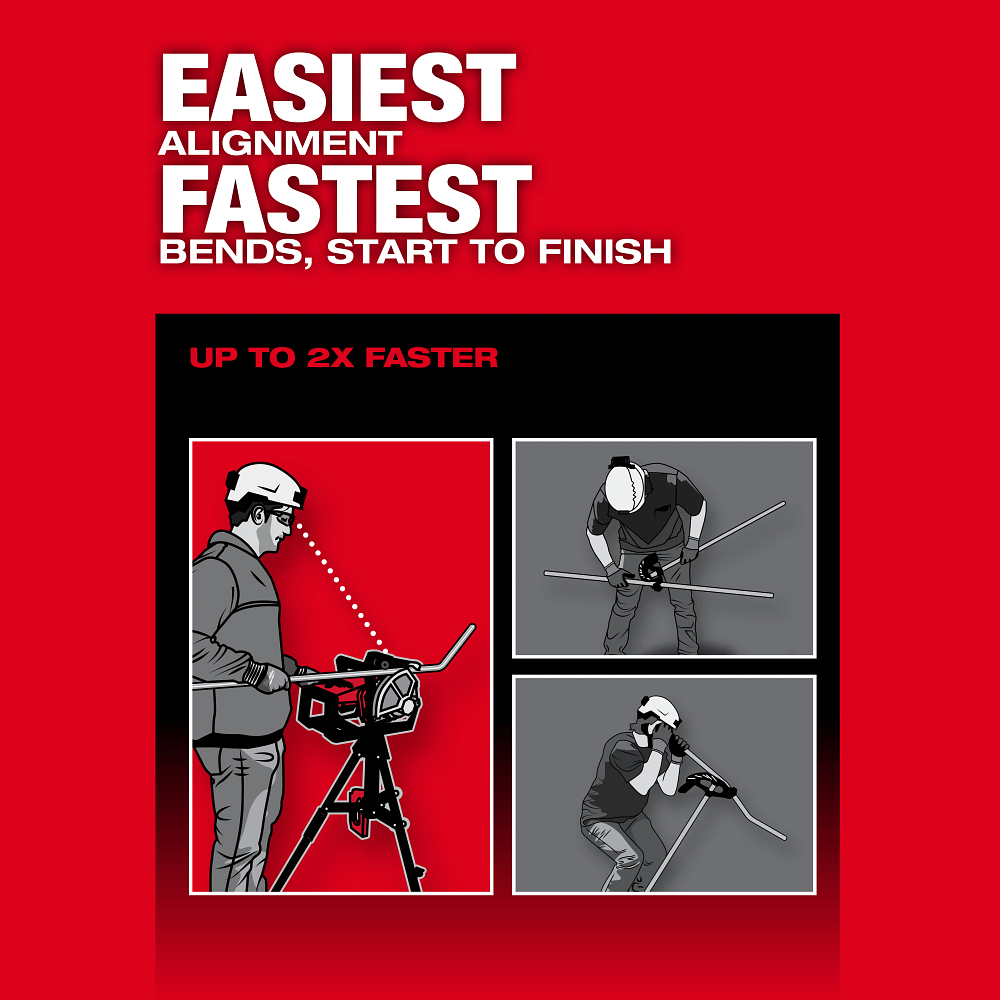

3. Faster Layout Alignment

Keeping layout marks in place while bending is a common pain point. With Milwaukee’s lock feature, electricians can secure their mark before making the bend. The tool also aligns layouts and bends in the same ergonomic position, making the entire process up to 2× faster start to finish.

4. Portability Without Sacrificing Power

Other powered conduit benders are stuck in one location and require a dedicated 20A outlet. That doesn’t work on most job sites. The M18 FUEL Branch Conduit Bender is cordless and portable, so electricians can bend conduit at the point of install, even on uneven ground.

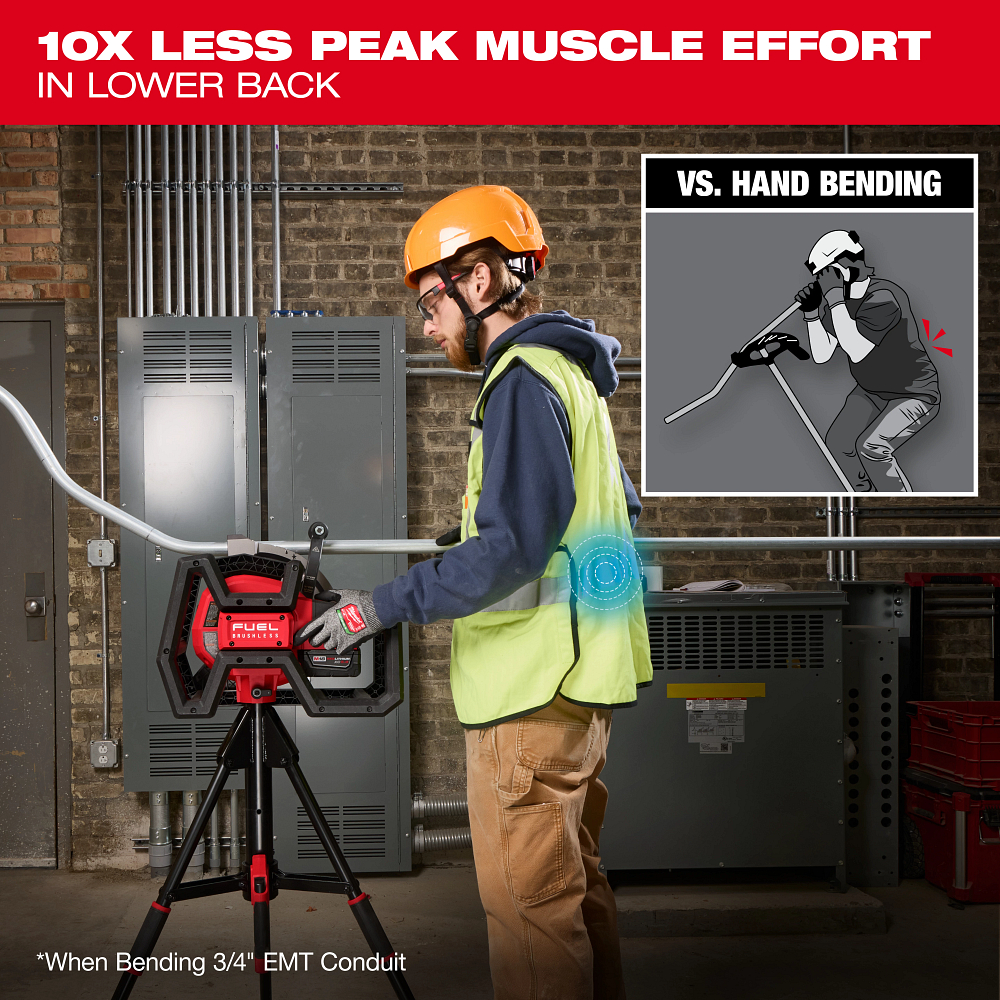

5. Reduced Physical Strain

Hand bending multiple conduits per day takes a toll on the body, especially the lower back. Milwaukee’s powered solution reduces peak muscle effort by up to 10×, protecting electricians from fatigue and injury while keeping productivity high.

6. Optimized for the Most Common Conduit Sizes

This tool is designed for what electricians actually bend most on branch jobs:

Shoes are interchangeable and follow the same geometry as hand benders, so electricians can use the same math and techniques they already know.

7. Ergonomic Jobsite Workflow

Instead of forcing electricians to bend over awkwardly to line up marks, Milwaukee’s design keeps everything in an upright, ergonomic working position. That means less strain and more accuracy, without sacrificing speed.

8. Cordless Productivity, Powered Performance

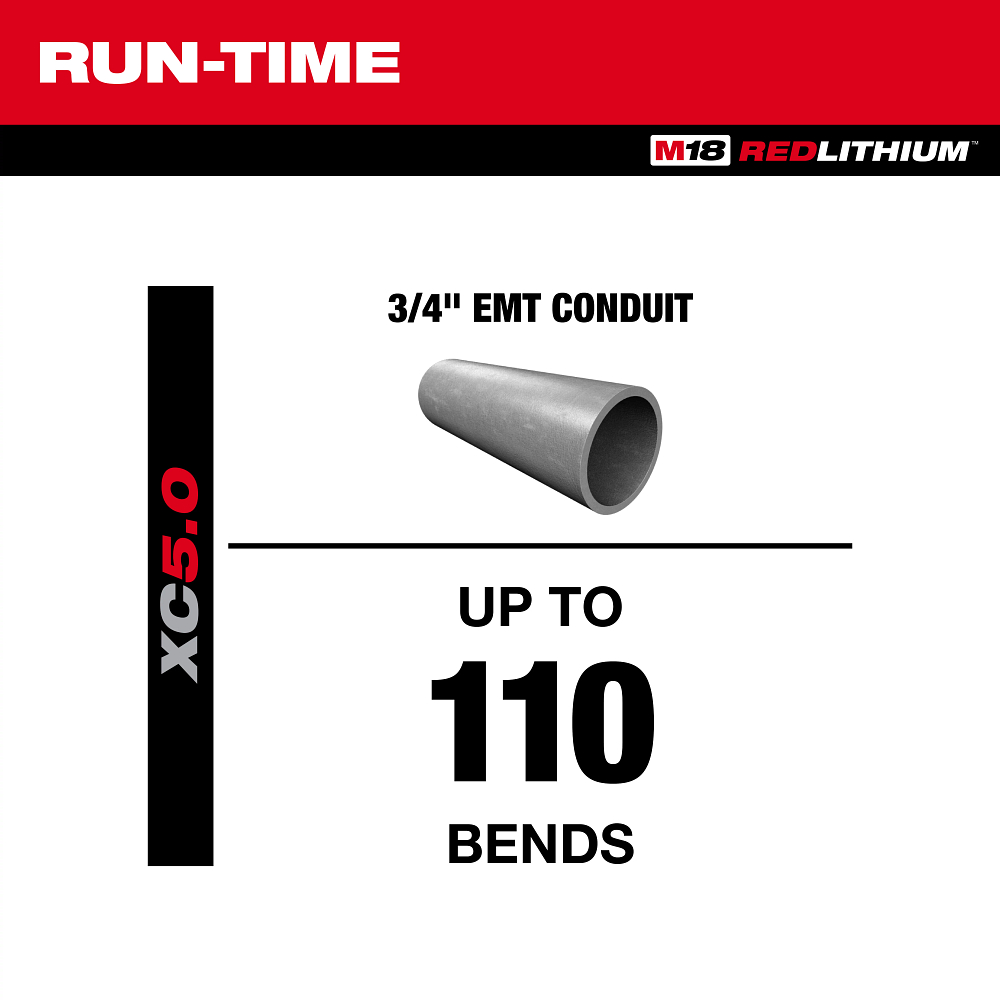

Backed by the POWERSTATE brushless motor and M18 REDLITHIUM batteries, the bender provides sustained performance without tying electricians to cords or generators. On a single charge, users can bend dozens of pieces of conduit, keeping jobs on schedule.

9. Solves Longstanding Bender Complaints

Electricians have been vocal about frustrations with conduit benders:

| Problem | M18 FUEL BRANCH CONDUIT BENDER |

| Poor consistency, Physically Fatiguing & Not portable. | Most Consistent Bends. Easiest Layout Alignment. Work Anywhere. Cordless Bending. |

| Guess and check leads to inconsistent results & Reworking required on most bends, multiple tweaks required. | Senses 0º every time ensuring consistent results. Automatically stops at target angle, reduces rework. Maximized productivity. |

| Printed springback charts don’t accommodate for batch-to-batch springback variation, leads to inaccurate bends & rework/scrap. | Built-in digital springback chart. Custom springback adjustments. Remembers custom springback settings for all materials, sizes, and angles. |

| Difficult to keep layout mark in the correct position while setting up to bend | Lock feature allows you to secure layout in place before completing bend and zeroes tool, reduces rework. |

| Not mobile, stays in central location on site, forces additional steps between tool and install. | Streamlines workflow by allowing cordless bending at point of install, including uneven surfaces. |

10. Productivity Gains on Branch Conduit Installations

Branch rooms and pipe racks often require multiple bends per pipe and multiple raceways installed side by side. Consistency is critical, and rework can derail timelines. Milwaukee designed this tool specifically for these scenarios, delivering: Repeatable accuracy, faster bends with fewer adjustments, portability to stay close to the work.

The result? Higher-quality installations with less time and effort.

Bonus: What You Need to Know About Shoes & Compatibility

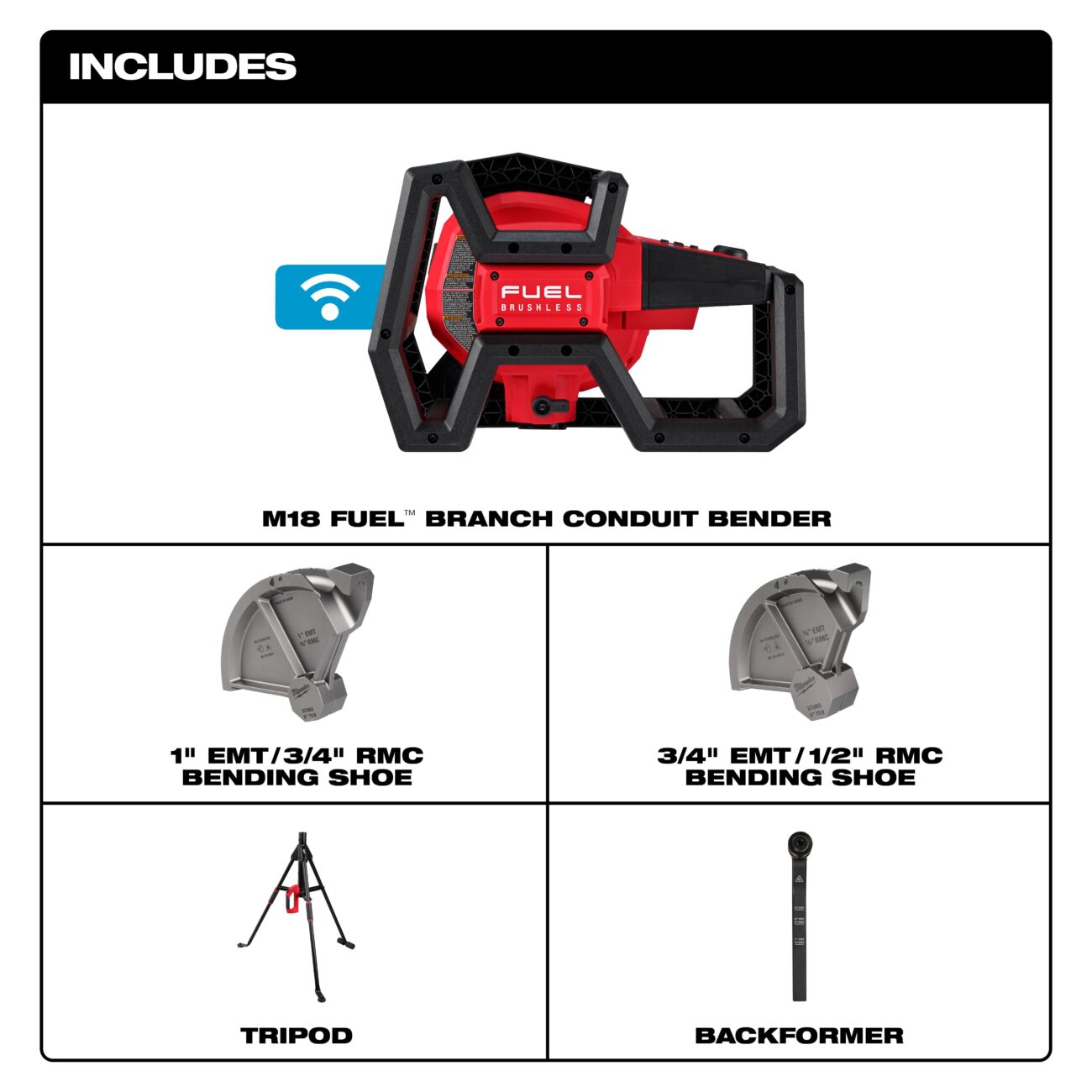

Included in Kit (5150-20)

½″ EMT shoe (49-16-0012) sold separately

Not Compatible With, Stainless steel EMT/RMC/IMC, PVC-coated RMC, or non-metallic conduit.

The M18 FUEL Branch Conduit Bender w/ AUTO-ZERO represents a true leap forward for commercial and industrial electricians. By combining cordless convenience with digital accuracy and reduced strain, it solves the exact problems tradespeople face with existing benders.

For contractors focused on productivity, consistency, and worker safety, this isn’t just another tool, it’s an upgrade to the entire conduit bending process. Don’t hesitate to reach out at cs@ohiopowertool.com or 614-481-2111 with any questions, comments, or concerns, and be sure to follow us on all your favorite social media channels to stay in the know on all the latest announcements, deals, news, and more!