|

Getting your Trinity Audio player ready...

|

For years, construction workers had two choices when it came to hard hats: a Type 1 full brim or cap style. They were simple, affordable, and got the job done. But when safety standards evolved and the industry pushed for more protection, a gap was exposed, literally. Side impacts, falls, and chin-strap failures were causing injuries that the old designs couldn’t prevent. That’s when Type 2 helmets came into play.

The problem? They were almost exclusively available in climbing helmet or cap styles, which meant no sun protection, no wide brim, and little consideration for the everyday needs of construction trades.

Now, in 2025, that’s finally changing. Type 2 full brim helmets are here, and they’re quickly becoming the new standard on jobsites.

Type 1 vs. Type 2 Helmets:

What’s the Difference?

Years ago, when the first push for mandatory hard hats hit construction, helmets were basic. They had suspension only, no chin strap, and were designed for top impacts, tools or materials falling straight down. But if you were struck from the side, or worse, slipped off a ladder or scaffold, that helmet could fly right off. Those early designs are now classified as Type 1 hard hats.

By contrast, Type 2 helmets are built for both top and lateral impact protection. They also require a more secure fit, often with chin straps and internal foam. For decades, these came in climbing styles, modeled after the helmets climbers rely on to protect themselves against sideways collisions with rock faces. Effective for safety, but not designed for tradespeople working long hours outdoors.

Why It Took So Long?

When safety experts began pushing for helmets with side impact protection and chin straps, manufacturers looked at other industries for inspiration. Football helmets were too heavy and cumbersome. Climbing helmets made more sense, they fit securely, absorbed lateral impacts, and stayed on during falls. But climbers didn’t want brims. They moved their heads constantly, looked upward most of the time, and avoided climbing in rain or snow.

That left construction workers stuck with helmets that met safety standards but didn’t meet their real needs.

It’s 2025, and the wait is finally over. Today, Type 2 full brim helmets designed specifically for the trades are hitting the market.

Key Considerations for Type 2 Full Brim Helmets

Heat Management

Early Type 2 climbing helmets had full foam shells, great for impact protection but terrible for heat. They trapped warmth like a cooler, leaving workers miserable in hot weather. The best modern designs solve this by combining suspension plus foam on the sides only, which still meets Type 2 standards while allowing airflow.

Vented models go a step further, though they’re not suitable for every trade. For electrical work, non-vented helmets remain a must.

Accessory Systems

Modern jobsites require more than just head protection. Workers need integrated systems for:

Face shields and visors

Eye protection

Hearing protection

Cooling accessories

Lights and headlamps

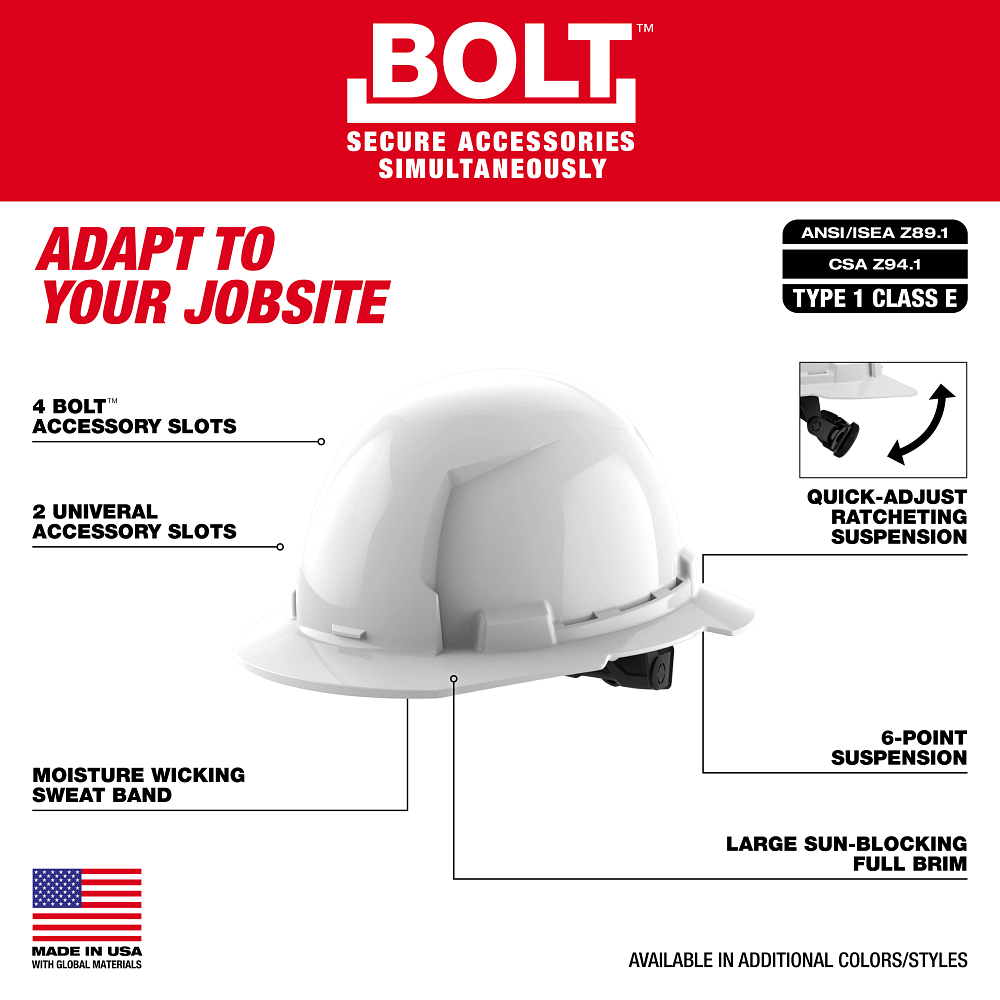

The challenge with full brims is making sure these accessories fit securely over the brim while still clipping into universal side slots. Manufacturers like Milwaukee (BOLT) have solved this by ensuring their accessories work seamlessly across both cap and full brim styles.

Branding & Professionalism

For companies equipping large crews, branded helmets are more than just safety gear, they’re part of the uniform. Both Milwaukee and Klein now offer interactive design tools for custom logos and graphics. Instead of sending in paper forms and hoping for the best, customers can preview exactly how their helmets will look before production. Ohio Power Tool also provides rendering services to make the process seamless.

Current Type 2 Full Brim Options

PIP Type 2 Full Brim

A price-point option that balances safety and affordability, making it ideal for outfitting large crews without breaking the budget. Built with a lightweight UV-stabilized HDPE shell to reduce fatigue and an EPS liner for front, rear, and lateral impact protection, this hard hat is designed for demanding job conditions. The 4-point quick-release suspension with a crown comfort pad and SURE LOCK ratchet system ensures a secure, one-hand fit, while the replaceable non-chafing foam sweatband maximizes comfort. Precise height adjustments allow for proper depth, and universal accessory slots accommodate face, eye, and hearing protection. Compatible with the 4-point chin strap (PIP280-HP542C), it meets ANSI Z89.1-2014 Type II Class E and CSA Z94.1 Type II Class E standards.

LIFT Safety Type 2 Full Brims

LIFT Safety Type 2 Full Brims bring premium protection and style to the jobsite, with both vented and non-vented models built for all-day performance. Long known for their carbon fiber shells and rugged durability, LIFT has stepped it up with the RADIX Full Brim line, available with integrated twiceme technology for next-level safety. The RADIX Vented Full Brim delivers lightweight comfort with a 12-channel ABS shell that keeps air moving, plus a LUX Retention System, oversized ratchet dial, and Dryline pads for a sweat-free fit. Its twiceme integration stores critical medical info, emergency contacts, and certifications, giving first responders instant access with a smartphone tap, no app required. For crews facing electrical hazards, the RADIX Non-Vented Full Brim is ANSI Type 2, Class E rated, offering dielectric resistance up to 20,000 volts alongside full crown and lateral impact protection. Both versions feature quick accessory integration with LIFT’s Arclite headlamps, hearing protection, and shields, plus magnetic chinstraps and moisture-wicking liners for comfort. Whether you need cooling airflow or Class E protection, the LIFT RADIX Full Brim helmets are built for serious pros who demand both safety and innovation.

Milwaukee BOLT Type 2 Full Brims

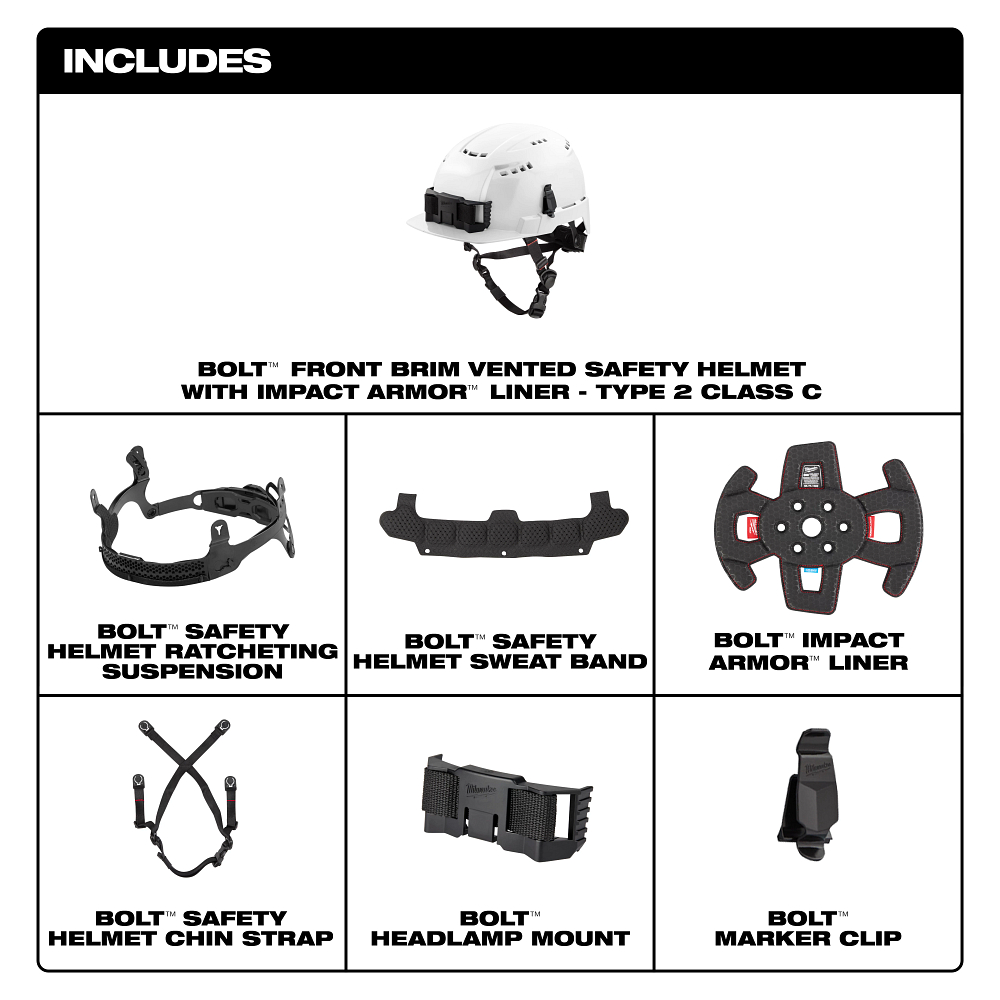

Milwaukee BOLT Type 2 Full Brims bring together advanced safety, comfort, and modularity in a helmet line built for today’s jobsites. Available in vented and non-vented versions, these helmets integrate seamlessly with the BOLT accessory system, allowing you to clip on visors, earmuffs, headlamps, face shields, or even cooling fans, no duct tape required. What sets them apart is Milwaukee’s IMPACT ARMOR liner powered by RHEON technology, engineered to protect against oblique impact forces that can occur during slips, trips, and falls. These kinds of impacts often pass dangerous rotational energy to the brain, which can lead to traumatic brain injuries. The BOLT Safety Helmet with IMPACT ARMOR is specifically tested to reduce those risks, providing unmatched side and crown protection.

Comfort hasn’t been overlooked either. Milwaukee uses a padded suspension with an adjustable swinging ratchet, plus a five-point chin strap with quick-adjust buckles for a secure, customizable fit, even while wearing gloves. Each helmet comes standard with a BOLT headlamp mount and marker clip for quick access to jobsite essentials, and all models meet ANSI Type 2 certification. For crews that want a professional look, Milwaukee also offers custom logo printing, giving teams a unified and branded appearance on site.

Whether you choose vented for airflow or non-vented for electrical protection, Milwaukee’s BOLT Type 2 Full Brim helmets deliver a complete head protection system: safer, smarter, and more adaptable than traditional hard hats.

The arrival of Type 2 full brim safety helmets marks a major turning point in jobsite safety. After decades of relying on Type 1 designs or adapting climbing-style helmets that didn’t fit the needs of the trades, construction professionals finally have access to gear that combines all-angle impact protection with the sun, weather, and glare defense they’ve always preferred. With manufacturers like PIP, LIFT, and Milwaukee, stepping up to deliver vented and non-vented models, modular accessory systems, and even smart technology integration, there’s now a solution for every trade and every crew size. Whether you’re looking for an affordable option to outfit an entire team or a premium helmet with advanced features, these new designs prove that safety, comfort, and practicality can finally go hand in hand. For the first time, the hard hat feels like it was built for construction, not borrowed from another industry. Don’t hesitate to reach out at cs@ohiopowertool.com or 614-481-2111 with any questions, comments, or concerns, and be sure to follow us on all your favorite social media channels to stay in the know on all the latest announcements, deals, news, and more!