The American construction industry is immense, composed of nearly 5 million workers and making up 4% of the US GDP. With each job comes its own set of obvious hazards and risks, and while not every person on the jobsite is at substantial risk, everyone in the area is exposed to hidden hazards. Below we discuss a few hidden risks that exist on construction sites that our friends at Protective Industrial Products (PIP) want everyone to be aware of.

UV RAYS

The sun obviously creates heat stress in warmer temperatures, but also can be a serious silent danger even in the cold months. In high temps, hot weather gear such as cooling PPE, shade and consistent hydration are essential to combat and prevent heat exhaustion, but this is not all to be cautious of. Overexposure to UV rays can lead to severe sunburn, sun poisoning and even skin cancer. This is why proper PPE providing the right level of protection against the sun’s rays must be provided to workers to truly care for the long-term health of your employees.

Did you know that you not only can sunburn your skin, but you can burn your eyes as well? Eyes, just like the skin, need UV protection. Shaded safety glasses are an obvious solution and are very efficient at protecting the eyes from UV rays and glare, but what about on cloudy days or when you’re working in dark or shaded areas? Clear lenses can be the less obvious solution, actually providing protection from 99.9% of UV rays. This applies to impact and non-impact rated eyewear, helpful for those working in the sun and/or dealing with UV radiation from a welding/metal working application.

Hard hats, like safety glasses, are another obvious safety necessity on the jobsite, but if you are working outdoors, it’s important that the hat can also withstand the effects of the sun. PIP offers an extensive line of hard hats (both vented and non-vented) that retain their color and structural integrity with prolonged exposure to sunlight. UV resistant features such as extended full brims and compatibility with hi-vis shading accessories minimize exposed areas of skin on the head, neck and parts of the shoulders to provide additional protection against sun damage.

HARMFUL NOISE

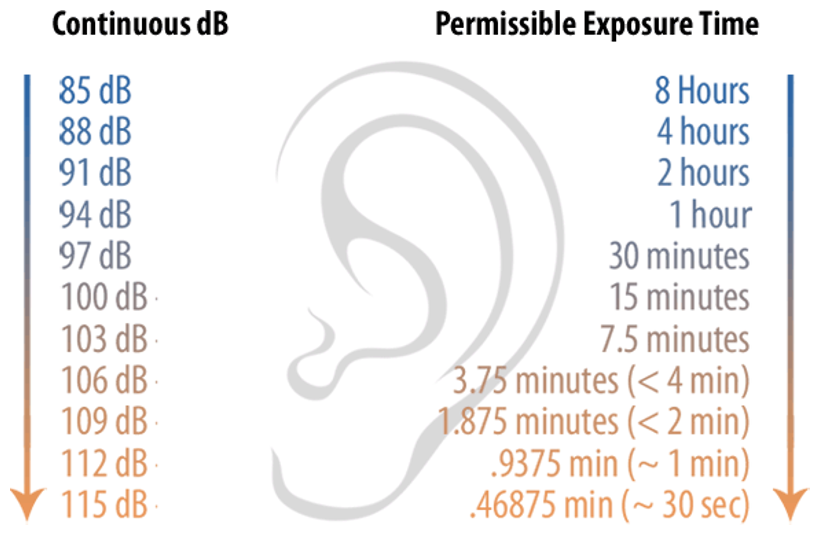

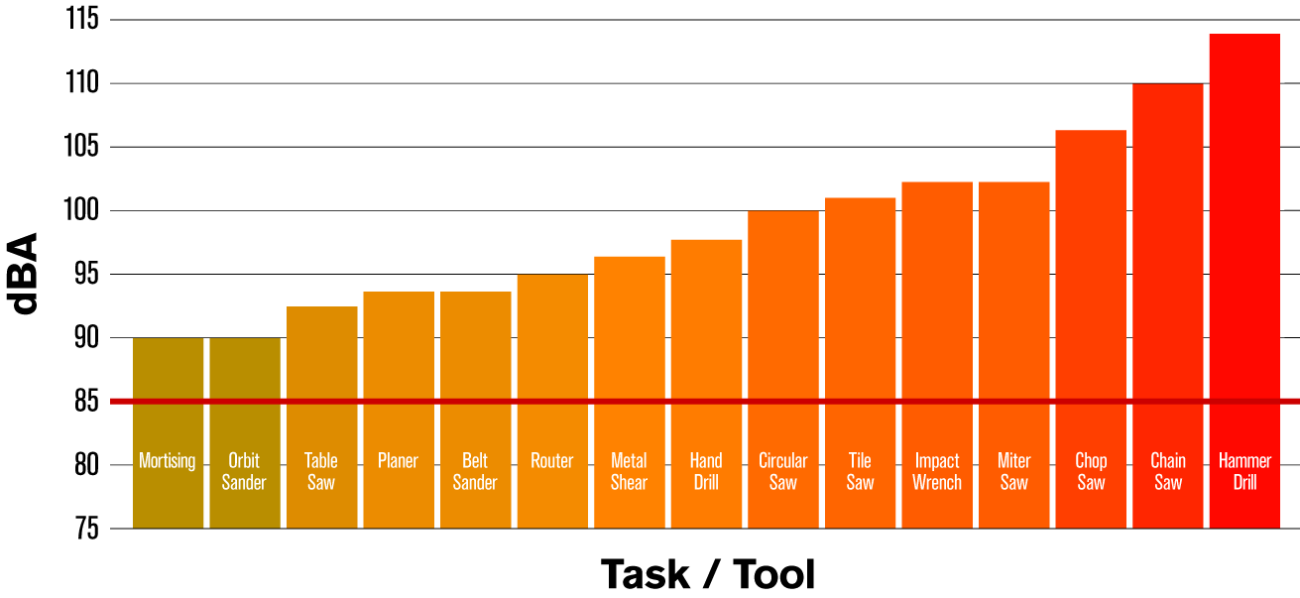

While most of us are aware of the dangers of exposure to noise on the jobsite, many ignore the risk of elongated exposure to these noises. According to NIOSH, about 51% of all construction workers are exposed to hazardous noise throughout the workday, with 31% of those workers reportedly not wearing hearing protection. The average continuous noise level of a construction site can exceed 90 dBA, which means that to avoid permanent hearing damage, one can only sustain roughly two hours of permissible exposure time without hearing protection.

Traditional ear plugs typically involve the removal of gloves to roll and apply the plug, or worse, ear plugs are applied with soiled gloves resulting in ear infections and other hygienic issues. This alone makes hybrid hearing protection an optimal solution for both ear canal health and time management on the job site when considering an alternative to earmuffs or traditional ear plugs.

To counter the use of soiled gloves and danger of not wearing ear plugs at all, PIP created ear plugs with a unique design which eliminates the need to roll the ear plug before fitting. A convenient handling stem located at the base of the foam allows you to gently press and twist the plug into the ear canal without the need of both hands. This is especially ideal in those unsanitary work environments where your hands or hand protection may be soiled.

FALLING OBJECTS

An obvious safety hazard on the jobsite is created when construction workers are working overhead with tools on scaffolding. This is common when working on infrastructure and commercial sites, but residential construction also can require working at heights, making dropped objects a threat to everyone below. Falling object prevention is imperative to the safety of ground-level workers. More than 50,000 injuries related to fallen objects occur annually. A tool weighing just two pounds has resulted in numerous cases of severe head trauma and even death in some instances when dropped onto the head of another worker from only 15 feet or higher.

The ANSI/ISEA 121 standard was created for this very reason, bringing a consistent set of guidelines to dropped object prevention and eliminating the allowance of the use of makeshift tethering solutions such as duct tape and fabric/string. The standard requires that the rated tool attachment be greater than or equal to the weight of the tool and that the tether weight limit and the anchor weight limit be equal to or greater than the weight allowance of the tool attachment. OSHA also requires employers to address dropped object hazards, which is now easier than ever to adhere to given the growing popularity of drop prevention and fall protection PPE.

BOUNDARY VISIBILITY

High Visibility work wear is common and an obvious necessity to ensure that workers are visible on a jobsite, but what about the boundaries and work zones of a jobsite? It is crucial that workers are alert at all times to avoid accidents in construction zones. In the course of a normal workday, most workers are exposed to deliveries, loading/unloading of materials, cranes, cement trucks and other activity on and off the jobsite–meaning that workers need to be aware of potential hazards at all times in all areas to stay safe.

Despite the fact that less than 9% of the workforce is on duty in the evening, 25% of accidents on jobsites occur at this time and more than half of fatalities caused by run-overs or back-overs involve construction vehicles. Such collisions have been attributed to limited visibility around equipment, with statistics concluding that 29% of workers were cleaning or repairing, 28% were walking along the road and 18% were directing traffic.

PIP: INNOVATION LEADING THE WAY

Often, construction is associated with “run of the mill PPE.” True construction and safety professionals, however, understand the complexity behind keeping hard workers safe. PIP works tirelessly to bring new and innovate safety solutions to the construction market. Just another way that PIP is able to Bring the Best of the World to You.

Have a question about PIP or other Safety products? Want advice on what safety protection is right for your job? The pros at Ohio Power Tool can help. Give us a call at 800-242-4424, email us at sales@ohiopowertool.com, or leave a comment below for assistance! To be the first to know about new products and deals, subscribe to our e-newsletter and follow us on social media!