Keeping the jobsite warm is one of the most important, and sometimes most difficult, aspects of working in the colder months. Not only can the cold affect the health and safety of you and your coworkers, but temperatures can also cause problems with a multitude of materials and surfaces on the jobsite. Cold stress can set in if you’re out in the elements for too long (this writer gets stressed in the cold almost immediately), which can lead to trench foot, hypothermia, frostbite, or worse, and ice buildup can create hazards leading to damaged equipment or injury. It’s imperative to have proper jobsite heating while you’re on the job in the winter, and that means much more than the singular space heater in the break room or that one trailer that has heat. The most common jobsite heaters are run by either propane or kerosene, and while it’s always a good idea to have a fallback should one fail, it may not be possible in some cases to keep and maintain both propane and kerosene on the jobsite. How, then, do you make the choice between the two?

Let’s take a look at propane heaters first. DeWalt will be our go-to for heaters here at Ohio Power Tool, and we’ve got a few options when it comes to propane. Generally, propane heaters such as these will be easier to maintain compared to their kerosene counterparts, due in the most part to two main factors; shelf life of the fuel and ease of upkeep. The shelf life of propane is indefinite, so you won’t have to ever worry about the fuel going bad or running foul. Maintaining a propane heater is a much simpler process as well; make sure the heater is kept clean and is free of any hazardous and potentially fatal leaks (a very important step; propane has neither an odor nor a color, and high concentrations of the gas emitted could lead to asphyxiation), and you’ll be set.

The personal-sized DXH12B gives off up to 12,000 BTUs of heat per hour, with its dual-tank setup ready to run for up to thirteen hours. It includes three USB charging ports for you to charge your phone or other electronics while in use, and runs off of DeWalt’s 20V Max battery line. The tip-over safety switch is designed to power the heater off should it befall any accidents while in use, and the LED strip included in the handle helps to illuminate the darkest of work spaces. Their larger DXH70C, on the other hand, is capable of giving off up to 70,000 BTUs of heat per hour, and is designed for larger jobsites. Using the same DeWalt 20V MAX battery line, the DXH70C uses its forced air expulsion system to bring the propane-based heat further into the jobsite than smaller personal heaters, and its split barrel design allows for easy maintenance at the end of the day. Propane tanks are much easier to store, as they can handle sun, rain, snow, or any other weather condition thrown its way; while not exactly recommended for safety purposes, one can even store propane tanks in a garage. The tanks may need to be painted over every so often to prevent rust, but should last quite some time. That being said, however, the tanks themselves can become quite heavy and bulky, which slightly lessens the portability of propane heaters.

Kerosene, on the other hand, has a much greater siphoning capability than propane, which leads to kerosene-based heaters such as the DeWalt DXH135 being much easier to transport around the jobsite (the DXH135 also has wheels which certainly helps, but let’s just skip past those for now). Kerosene itself has a potent smell and usually has some sort of dye injected into it for easy identification in the case of leaks or spills. The drums or canisters used for storage are typically cheaper than those used for propane, as is the gas itself if you can find it at a pump nearby. If you’re a budget-conscious person and can’t find any kerosene at a pump in your immediate area, you may want to factor in potential travel costs that may offset the difference between the two at the pump; if you’re running low and need a quick refill, are those twenty cents or so truly worth it, or would you rather just run and pick up a propane tank, found at nearly every gas station in America? Storing canisters of kerosene is also a much more conscious task; canisters must be stored in a cool, dry place that avoids direct contact with sunlight. A shed would be the ideal storage space for kerosene canisters, though this may not be possible in all cases. You’ll also want to use your kerosene up before it goes bad, which is typically within two to five years; additives can be introduced to your supply of kerosene to extend its shelf life, but this also increases the overall cost of operating a kerosene heater.

Both kerosene-based heaters and propane-based heaters put off an amount of moisture during operation; a moisture removal system is one of the most important things one can use while operating these heaters, thereby mitigating the chances of mold, corrosion, or rot setting in to building materials around the jobsite. Per gallon of fuel burned, propane gives off significantly less moisture, at .98 gallons compared to kerosene’s 1.1 gallons. The difference may not seem like a lot on paper, but that condensation could add up and accumulate throughout the workday, leading to the aforementioned corrosion, rot, and mold problems, as well as creating potential ice hazards around hundred and thirty degree metal; all of this without even touching the issue of air pollution. Both propane and kerosene heaters create an amount of air pollution, giving off carbon monoxide, carbon dioxide, nitrogen dioxide, and sulfur dioxide; buildup or prolonged exposure to these could be hazardous or potentially even lethal, and proper ventilation systems and carbon monoxide detectors are absolutely paramount when operating these heaters.

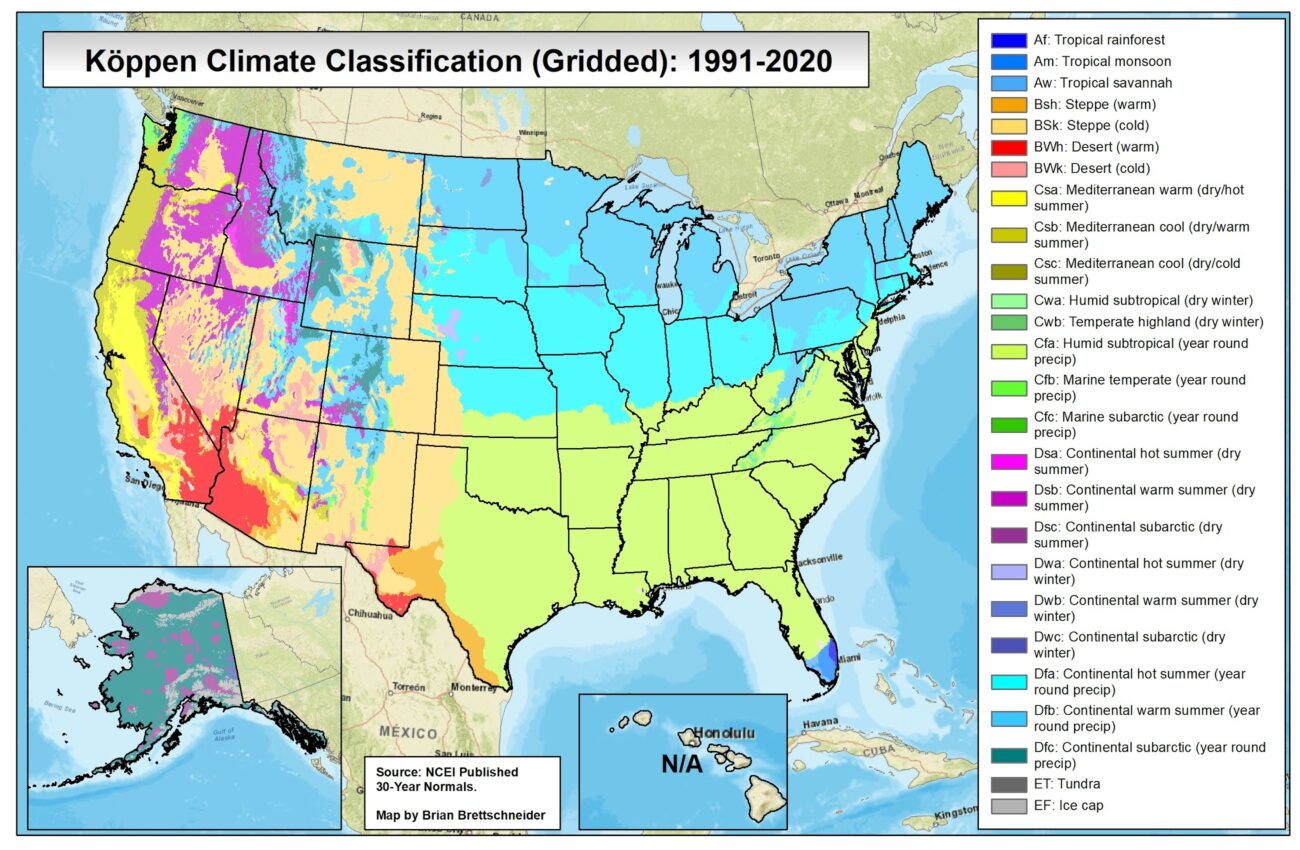

Now, some may be asking how one can tell how many heaters, or at least how much heat is needed to properly heat their jobsite, and the answer truly depends on a variety of factors; weather, material being used during the day, and location of the jobsite itself, are all brought into account when determining this answer, as well as the climate zone in which you reside (or are at least on the job in). In 1884, German-Russian climatologist Wladimir Köppen broke down the five climate zones that one encounters in the world (German climatologist Rudolf Geiger would go on to make some additions to the model in the late 1930s, leading to its sometime being called the Köppen-Geiger model), all five of which we can see right here in the United States, and all five of which require different British thermal units, or BTUs, of energy to properly heat and maintain.

Zone A, for example, which Köppen lists as Tropical, can be likened to the southeastern portion of the country, with an average temperature of over sixty-four degrees and significant precipitation; this area would require about thirty to forty BTUs per square foot of space for proper heating. See the table below for the full list of climate zones and their respective BTU requirements. Many places online have calculators if you’re looking for a quick way to get the proper amount of BTUs, but a general formula of (cubic feet of space) x (desired temperature change) x .133 can also be used.

| CLIMATE ZONE | BTU REQUIREMENT |

| A (TROPICAL) | 30 – 40 |

| B (DRY) | 30 – 40 |

| C (TEMPERATE) | 40 – 45 |

| D (CONTINENTAL) | 40 – 45 |

| E (POLAR) | UP TO 60 |

As we said at the start, keeping the jobsite warm can be one of the most difficult aspects about working during winter; office workers and even those in retail or food service have it much easier when it comes to keeping their workspace warm, but for those out in the field all day, we hope this was helpful in heating you up. As always, if you have any questions, feel free to drop us a line at 614-481-2111 or at sales@ohiopowertool.com, and be sure to follow us wherever you get your social media to stay up to date on deals, news, and more!