Splurging on new high-powered tools is always fun but taking the time to choose the right extension cord to power them is often overlooked. Without the proper power cord, your tool may not perform properly and there is a greater risk of fire and electrical shortages. Customers come to us all the time with tools that have shorted out or broken from using them with the wrong extension cord. Many fail to realize that using an extension cord that is not equipped to handle the power output of the tool can cause a variety of problems such as fires, voltage loss, and damage to your tool. To demonstrate this, we tested the amperage of the powerful 12″ Dual-Bevel Sliding Compound Miter Saw with Laser (LS1219L) with different gauge extension cords to see how the saws amperage holds up with each cord. Before we get into the results of our test, let’s go over the basics of how to find an extension cord that is suitable for the tool you’re powering.

Sizing Your Cord

The first step to finding the right extension cord is checking the motor amperage of the tool or appliance you are using, which should be printed on each tool. Make sure that the extension cord you use has either the same amperage or more, so you don’t damage the cord or your tool. Both the length and gauge of the extension cord makes a difference in how it performs. It is better to use the shortest cord possible because it lessens the amount of friction that travels through the length of the cord. If you are using a 100ft. cord in an area that really only requires a 25ft. cord, you may have voltage drop, which is the loss of voltage as it travels down the wire. As the electricity flows down the wire it encounters resistance which creates heat. The longer the cord, the more resistance, so the hotter it gets which can be dangerous.

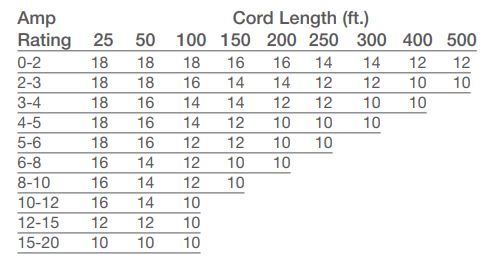

The wire gauge refers to the thickness of the copper wire in the cord, and it determines the amperage load each cord is able to manage while in use. The thicker the cord, the more amps it can handle. For 10-, 12-,14-, 16-, and 18-gauge cords (10-gauge being the largest and 18-gauge being the smallest) you can use the following chart as a guide to determine what gauge cord to use based on your tool’s amperage and the length of the cord.

It’s important to always check the amperage of your extension cord before using it. Using too small of a cord can overheat it and cause fires or damage your tools. Additionally, if you are powering multiple tools at once with one cord, you should add up the amperage on each tool to make sure the cord is strong enough to power them. It’s also a good idea to keep a circuit breaker around to prevent cords from overheating.

Common Tool Amperages

- Oscillating Multi-Tool 2-4amps

- Drills 6-10amps

- Sanders 2-10amps

- Grinders 7-15amps

- Rotary Hammers 10-15amps

- Circular Saw 13-15amp

- Routers 13-15amps

- Core Drills 15-20amps

Different gauge cords might be suitable for quick usage, but over time they can cause a lot of issues for you and your tool because of over heating and voltage loss. Checking the amperage and gauge of your extension cord with each sue can save you a lot of time and money in the long run by avoiding damage to your tools. Still not sure which type of extension cord to choose? The Ohio Power Tool team is here to help! Give us a call at 800-242-4424, email us at sales@ohiopowertool.com, or leave a comment below for assistance. To be the first to know about new products and deals, subscribe to our e-newsletter and follow us on social media!