At the Water & Wastewater Equipment, Treatment & Transport (WWETT) Show earlier this year, RIDGID announced and debuted their brand-new pipe patching system that is designed to complete up to 6ft trenchless pipe repairs in 2” to 6” lines. This versatile new system is a huge addition to RIDGID’s product line, introducing a cost effective pipe rehab solution by placing durable fiberglass patches in p-traps, bends, transitions and straight sections of pipe with a single kit. Pipe patching surpasses ASTM F1216 requirements for structural integrity while also providing a fast ROI, short learning curve, and a less invasive process when compared to other pipe repair methods such as digging. For those of you working on pipe inspection and cleaning, this means an affordable and easy way to make your business an all encompassing one-stop solution for your customers, with the ability to make you thousands of dollars more on jobs that need repair work.

What is Pipe Patching?

For years, CIPP (Cured in Place Pipe) patching has been used globally as a structural repair method in short sections of broken and damaged pipe. Patching, while a great standalone additional service offering, is also seen as a gateway into full length lining due to the relatively low initial cost and high return on investment, combined with a short learning curve for installers. For these reasons, patching is considered the best way to enter the CIPP market.

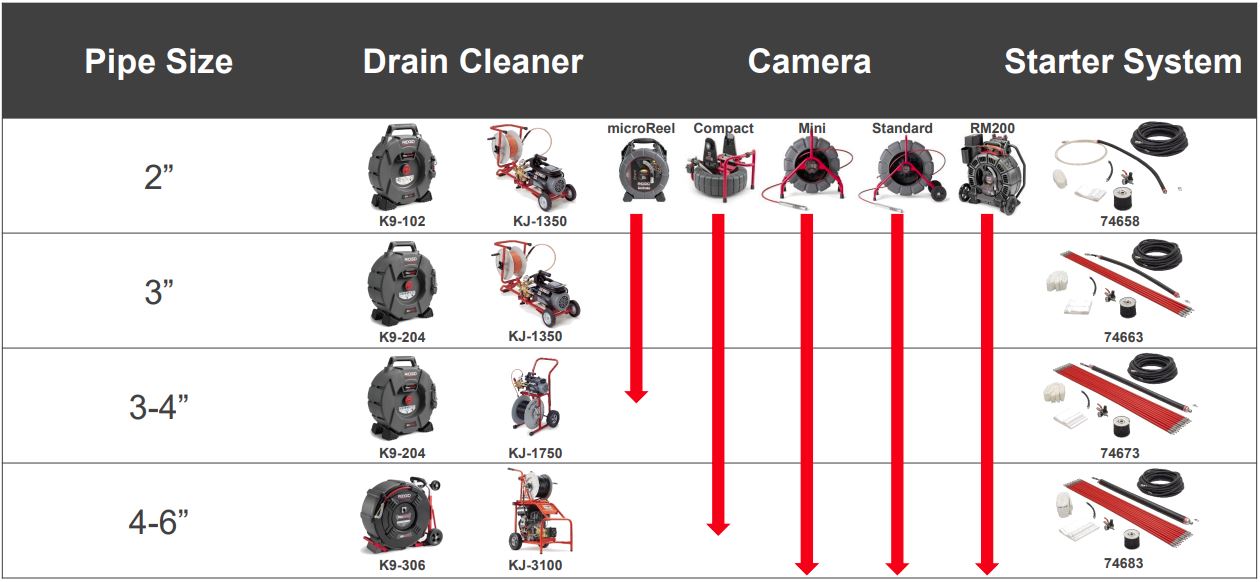

RIDGID Pipe Patching Starter Kits

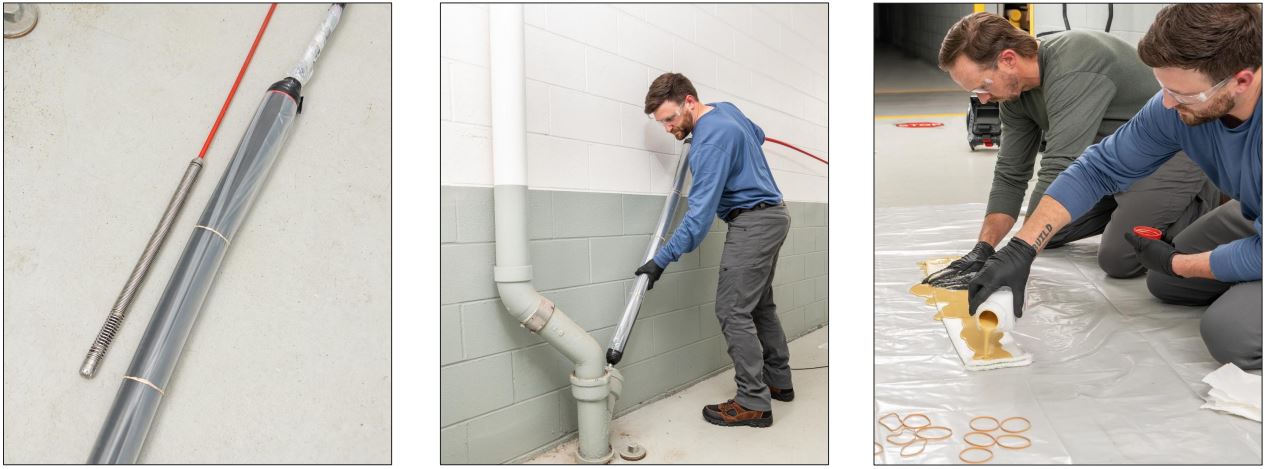

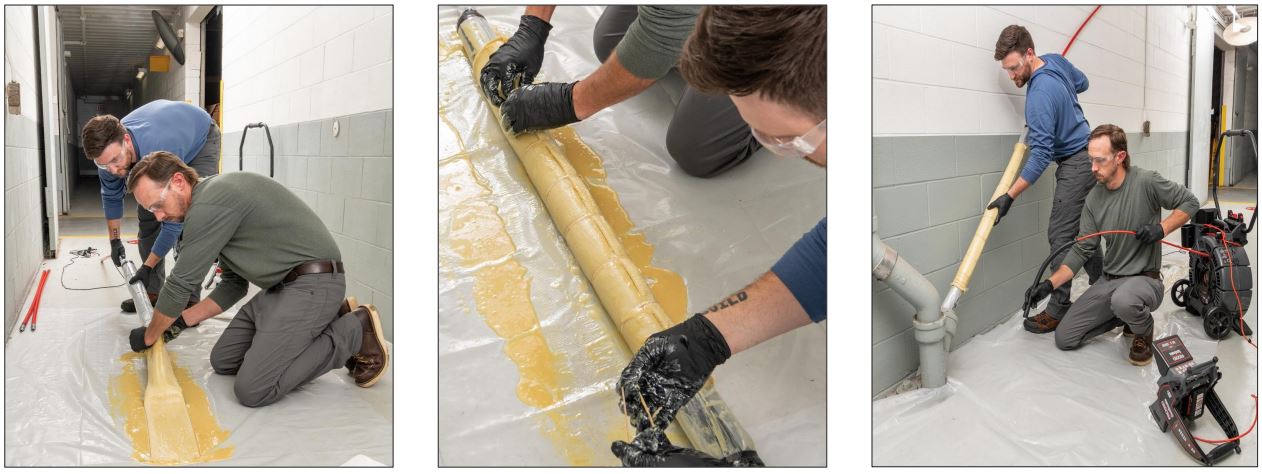

The new RIDGID Pipe Patch Starter Kits allow for quick and efficient fiberglass patch repairs. Each kit comes with versatile packers, air push rods & necessary components that accommodate p-traps, bends, transitions & straight sections. The Packers can be pushed or pulled into place through multiple pipe configurations such as straights, bends, transitions and p-traps. Once they are inside the pipe, they are inflated to push the resin-coated fiberglass liner onto the walls of the pipe, closing up the damaged area. The Air Push Rods are used to push and rotate the Packer into the precise placement needed to complete your repair. They are flexible enough to navigate through bends and have lockable fittings to extend them as needed and prevent them from disjoining while in use.

RIDGID will also offer Pipe Patch Kits (non starter kits), which come with the resin, gloves, bands, surface covers, and all the materials you need to complete a pipe repair project. These are going to be single-use kits for completing one repair, so when you get the job done, you can simply pick up a full new kit and move along.

How To Use the Pipe Patch Kits

1. Inspect the line, confirm the patch locations, and prep the packer

2. Confirm the packer can reach the patch locations

3. Wet the fiberglass patch

4. Place fiberglass patch onto packer

5. Use elastic bands to secure the patch to the packer

6. Push or pull the packer into place, inflate, and allow time to cure

RIDGID Solutions

The goal of this new patching launch was for RIDGID to be able to offer a complete range of equipment to complete pipe work from start to finish. RIDGID’s Drain Cleaning Machines and Water Jetters can be used first, to clean out pipes and ensure there is no debris or buildup blocking it. Their SeeSnake Video Inspection Systems can then inspect the inside of the pipe and locate the source of the damage. Then, finally, the Pipe Repair kits can fix any repair problems with minimal effort.

The RIDGID Pipe Patch Kits are available for pre-sale NOW at Ohio Power Tool! If you have any questions about these kits or any other pipe maintenance and repair options from RIDGID, give the team at Ohio Power Tool a call at 800-242-4424, email us at sales@ohiopowertool.com, or leave a comment below for assistance. We’re always happy to help! To be the first to know about new products and deals, subscribe to our e-newsletter and follow us on social media!