It’s officially Fall, which means the days are getting shorter and we are left with less daylight hours for working. Professionals that work early or late hours are going to need temporary lighting solutions to ensure that their work areas are adequately lit without the aid of sunlight. When it comes to temporary lighting, there are tons of options out there to fit different jobsite layouts. At Ohio Power Tool, we are proud to be partnered with manufacturers like Southwire, that offer some of the best temp lighting options available, ensuring you won’t be left in the dark when choosing the right setup for your workplace.

Lighting 101

Before we get into specific lighting models, it’s important to understand how different lights are classified and when each type is needed. Knowing the color and brightness of your lights is the key to making sure they are providing adequate lighting for your application. The color of a light is measured by a heat scale, known as Kelvins, and the brightness is measured in Lumens.

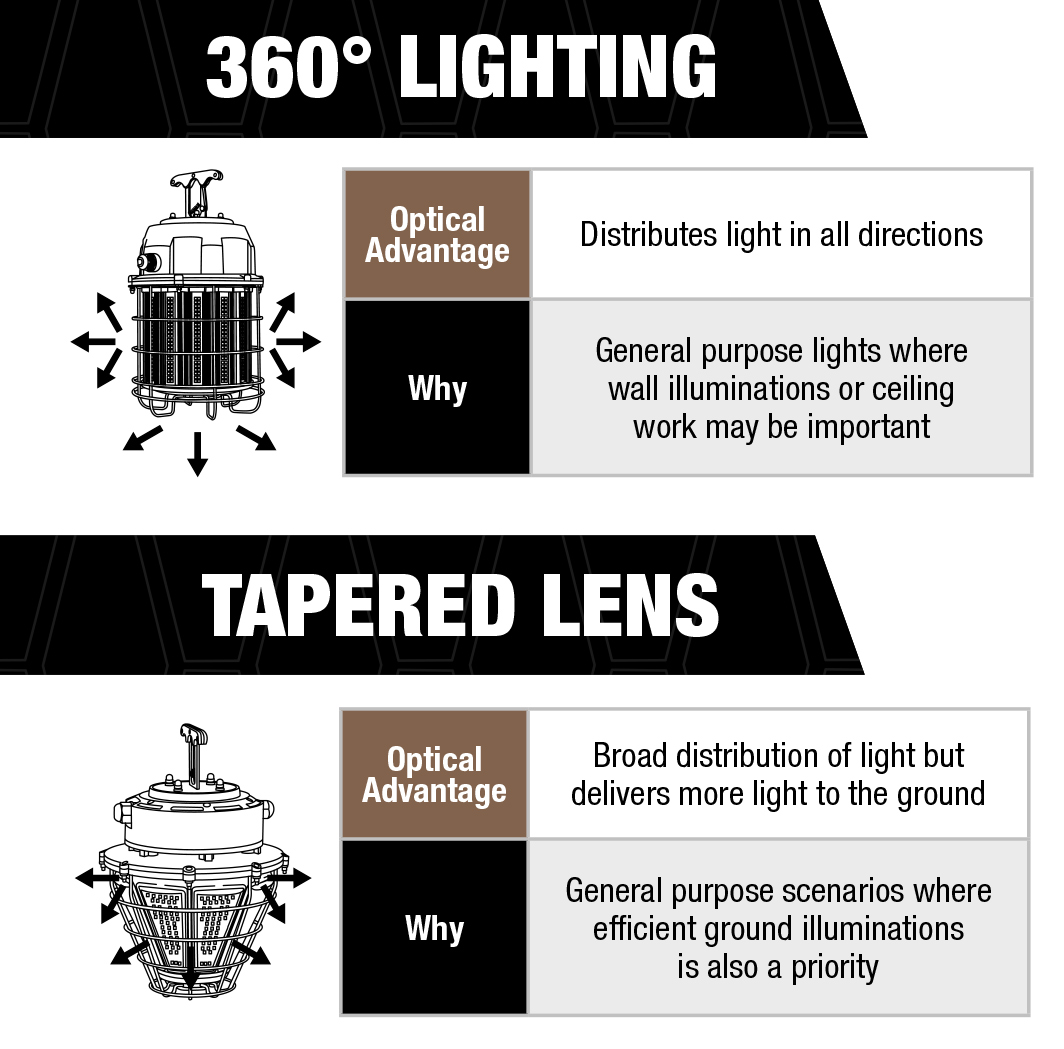

When choosing jobsite lighting, your main consideration should be the space that needs illuminated. Are you hanging the lights, placing them on beams or walls, or setting them on the ground? How much area do you need to cover? What direction does the light need to go? These are all important questions to ask yourself or one of our on-staff lighting experts. We are here to help you identify the right lighting solution for your job and help you make an informed purchase.

Another aspect to consider is the wattage needed to power your temp lights. Most lighting options will clearly state their wattage, so it is important to check your power source to make sure you don’t overload it. While we’re on the topic, Southwire is one of the largest cable and extension cord manufacturers in North America, so if you’re in need of a better-quality cable to power your lights, theirs will definitely not disappoint.

OSHA Rules and Regulations

OSHA has strict requirements for jobsite lighting, so hopefully we can help shed some light on best setup for you based on your environment and individual needs. All work areas and walkways are required to be adequately lit whenever employees are present. The chart below lays out how each area of a jobsite should be lighted to follow regulation, preventing any injuries or workplace hazards.

| Lumens/ft2 | Area of Operation |

| 3 | Concrete placement, excavation and waste areas, access ways, active storage areas, loading platforms, refueling, and field maintenance. |

| 5 | General construction area lighting |

| 5 | Indoors: warehouses, corridors, hallways, and exit ways |

| 5 | Tunnels, shafts, and general underground work areas. Exceptions apply: for shaft and tunnel heading, ten foot-candles is the requirement for mucking, drilling and scaling. Bureau of Mines-approved cap lights are also acceptable. |

| 10 | In general shops or construction plants such as screening plants, batch plants, carpenter shops, mechanical and electrical equipment rooms, rigging lofts, active storerooms, mess halls, and indoor toilets and workrooms. |

| 30 | First aid stations, infirmaries, and offices. |

Choosing the Right Light

The amount of lighting solutions available for construction sites are seemingly endless. In order to identify the correct type of lighting for you, it’s important to be cognizant of your jobsite layout, the applications you will need lighting for, and the regulations that must be met. A small project may only require a single area light, whereas lighting a multi-floor apartment complex, hospital, etc. may require hundreds of overhead hanging lights. To equip your jobsite with a code compliant lighting setup please reach out to one of our lighting experts through our Custom Lighting Portal. We offer free quotes and schematic layouts of lighting solutions custom to your jobsite. Simply fill out this form and one of our representatives will reach out to help. To get a better understanding of some of the options available, here’s a breakdown:

Overhead Lights

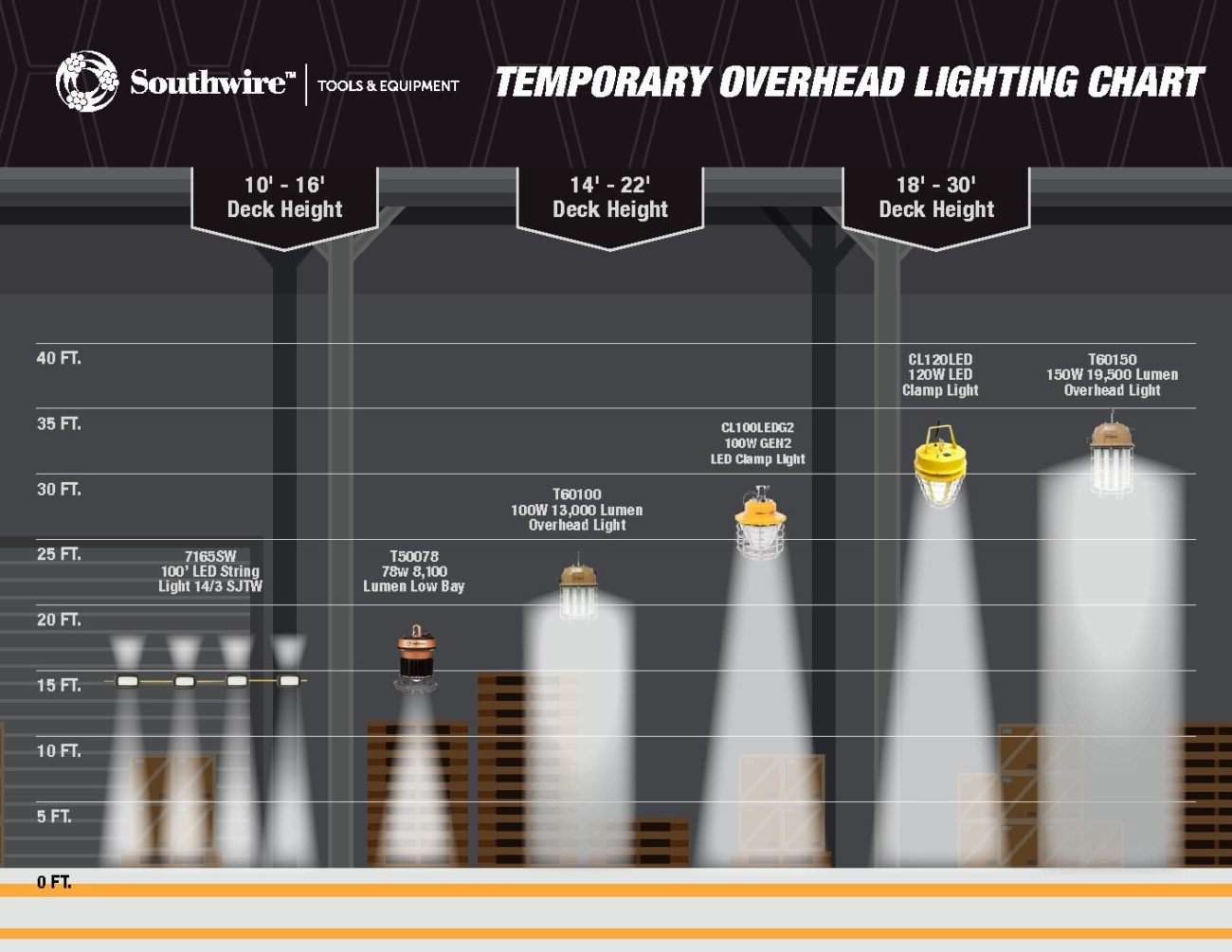

Overhead lighting can be suspended from ceilings or rafters for all around lighting. When choosing an overhead light, be sure to account for the height of space and select a light that can adequately fill it. If you are hanging your overhead lighting high above your workspace, 30-35 feet for example, we would recommend choosing a light that is 15,000 to 20,000 lumens, such as the Southwire 15,000 Lumen 150W LED High Bay Light (111200LED). A light this size will easily reach all the way to the ground. Depending on the square footage of your area, multiple overhead lights might be needed to fill the entire space.

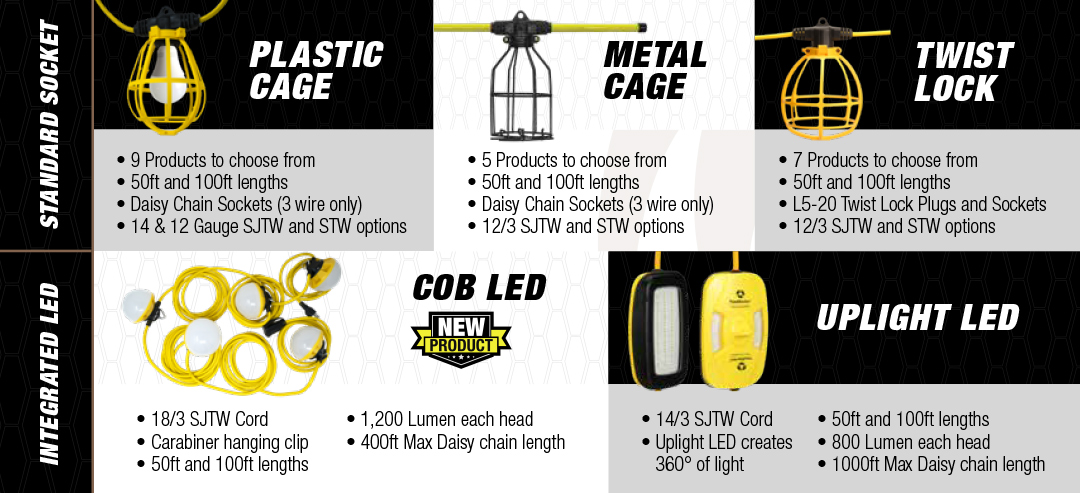

When working with slightly lower ceilings—20 feet high max—or smaller areas, low bay lights and string lights are great options. String lights are very common in construction zones because they are fairly easy to set up and can be daisy-chained together to cover more surface area. The Southwire 100-foot 8,000 Lumen LED String Lights (7165SW) are a very popular string light solution. They are IP65 outdoor rated to protect from water and dust, and has LEDs built into the line for extra durability so you don’t have to worry about replacing faulty bulbs. For a slightly more cost effective option, we recommend the Southwire 100-foot 10-outlet Light String (7145SW). These string lights have standard medium light sockets, so they can be used with incandescent bulbs or with LEDs for a slightly higher upfront cost but lower overall cost and maintenance. Stairwells, hallways, first aid stations, and smaller areas in work zones are common locations for string lights.

Area Lights

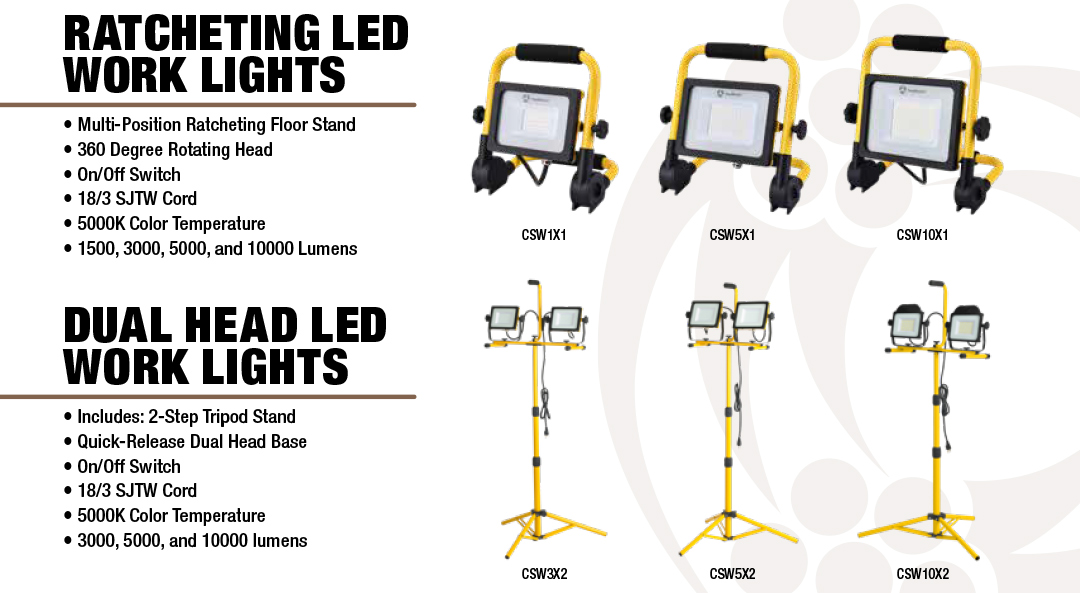

Area Lights are a great versatile and portable lighting solution that can be used in pretty much any setting. A popular area work light is the 1000-Watt Halogen Twin Head Work Light (L13SW), which features dual easy-to-adjust heads, a telescoping base for height adjustment, and two on/off switches that control each head individually. This light is also available in an LED option. LED lights are more efficient, better for the environment, and have a longer lifespan, making them the more cost-effective option with long-term usage.

Wobble Lights

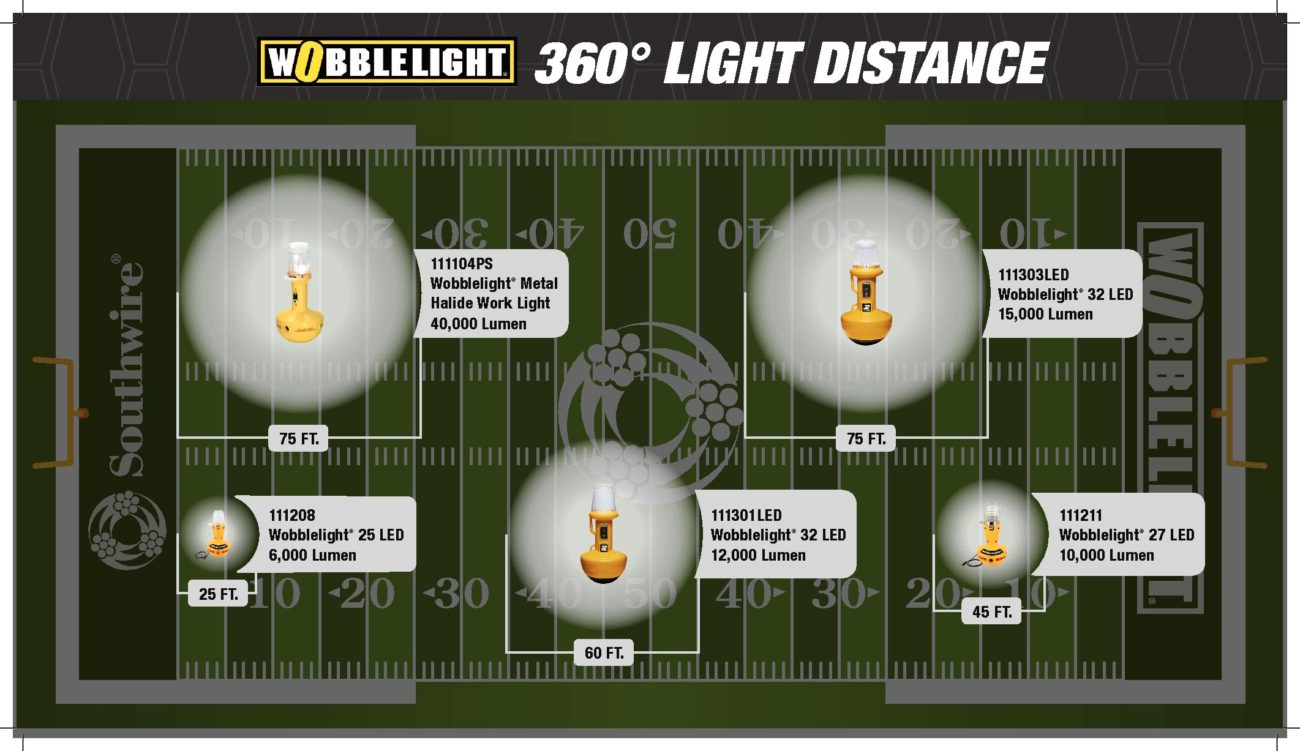

Southwire’s Wobblelights are the perfect solution for those who need a durable light to withstand a chaotic jobsite. These lights provide 360-degrees of light for your workspace and use counterbalance in their rounded base to keep them from falling over, which means no more tipping light towers and broken bulbs.

Most Wobblelight models are designed to be interlinked, which makes them great for large job sites. The V2, Metal Halide, and Halogen Wobblelight can be interconnected to illuminate an entire jobsite. The V2 and V3 Wobblelights have a visibility range of 60-75 feet in diameter, while the smaller Wobblelight Jr. has a shorter range of 25 to 35 feet.

Ready2Hang Light Program

If you have a large jobsite and need to order and install a large quantity of lights, let us do the hard work for you! Southwire’s unique Ready2Hang Lighting Program allows you create the most efficient lighting layout for your space with minimal packaging and clutter. Work with our team to identify the right lighting solutions for your jobsite, and then your kit will be delivered to you with all the necessary elements including extension cords, temp power boxes, and more! Everything is safely packaged and ready to use, as the name suggests, which saves you time and money with a stress-free installation.

No matter the job, there is a lighting solution out there for you. Have any additional questions about temp lighting or how we can help you create the perfect lighting setup for your home or jobsite? Give us a call at 800-242-4424, email us at sales@ohiopowertool.com, or leave a comment below for assistance. We’re always happy to help! To be the first to know about new products and deals, subscribe to our e-newsletter and follow us on social media!