The most common way to drill smaller holes into concrete, without question, is with a hammer drill and carbide drill bit. We regularly get questions about these, but first, and one of the most common, is what’s the difference between some combination of SDS-Plus vs SDS-MAX vs Spline bits? Our video below covers all of that, but assuming you’ve already got your weapon of choice, the other big questions we get are on the carbide drill bits themselves and “Cutter Heads”. Here’s a quick rundown of the basics to highlight the differences between 2-Cutter Heads, 4-Cutter Heads and Full Head Carbide, which will hopefully help you pick the Right Tool for the Job.

Where’s the Beef?

The number of “cutters” or “points” on a carbide bit is essentially talking about the geometry of the head. Traditionally, a single piece of carbide was put in a slot of the steel bit, because carbide is hard and can handle constant pounding and drilling in concrete much better than pretty much anything else. As tools have become more advanced, new designs have come about, but this can be a bit misleading as well. The amount of carbide itself tells more about the longevity of the bit rather than the shape, and nobody really measures the carbide amount, quality or depth.

The 2-point is the original model–a piece of carbide in a slot where there is a “cutter” on each side. The 4-cutter is similar, forming an X-shape where the pieces of carbide cross, creating 4 points/cutter edges. There are even 3-cutter and 6-cutter designs out there, just for brands to say “if you want more cutters, we got ’em!”, but these are far less common. Full Head carbide basically means that instead of simply being a slot of carbide, the entire head becomes one solid piece and is welded onto the steel. Typically, Full Head carbide can be any configuration of a 4-cutter cross, but with smaller pieces it is actually more similar to a rectangle that’s all carbide.

Size Matters!

With smaller size carbide bits (under 1/2″), SDS-Plus and SDS-Max 2-cutter vs 4-cutter matters less and less in terms of speed–there’s just not that much surface area to work with. That’s not to say that there aren’t faster, better, longer lasting bits, certainly there are better ones, but the number of cutter points means less the smaller you go. The smaller Bosch Full Carbide “Bulldog Xtreme” bits, for instance, are basically a solid 2-cutter full head carbide, and from what we have seen with thousands of bits sold, these have performed the best out of all of the smaller diameters up to this point.

When you get to 1/2” and larger carbide bits in either SDS-Plus, SDS-MAX or Spline, you ideally should be going to a 4-cutter cross geometry. The larger you get, the faster the speed, lower the heat and longer the life due to the cross design of the bit. You’ll still have the option of 4-cutter slotted vs. 4-cutter full head carbide, but the full head will have even better performance and an even longer life. Certainly they make 2-cutter carbide in larger ¾” or 1” sizes, but at that point it’s just to lower the upfront price–performance will be much slower and they will not last as long, so we’d recommend staying away from them if you can.

Diablo Rebar Demon vs. Bosch Bulldog Xtreme

The new Freud Diablo Rebar Demon bits are now available, and as the name suggests, they have no issues hitting Rebar–the mortal enemy of carbide bits. The Rebar Demon line is a full head carbide line with other, less expensive Diablo 2-cutter and 4-cutter slotted carbide options that will follow.

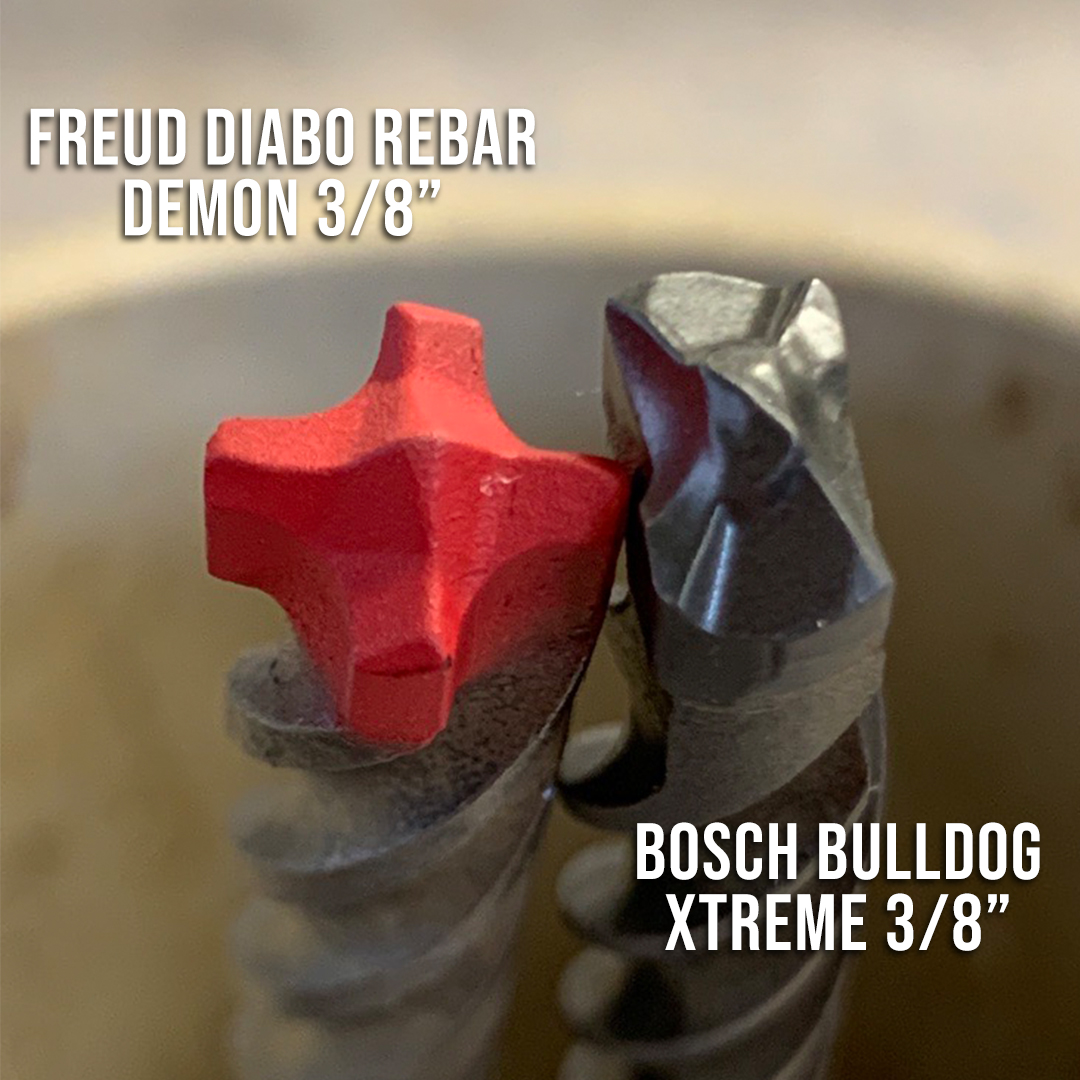

The Freud/Diablo Brands are owned by Parent Company The Bosch Group, which of course is also the same parent company for The Robert Bosch Tool Corporation. Carbide bits from both brands are produced in a factory owned by the parent company in Germany, so naturally we initially thought that they were the exact the same bits–Bosch Blue stickers going to one box chain store and Diablo Red going to another box chain store, same bits…different color. However, that is not exactly the case.

As you can see with the 3/8” diameter, they do have a slightly different Full Head Carbide configuration, but we’ve done some initial testing and have seen that there is nothing too noticeably different in speed with the new bit. It’s certainly possible that there could be differences in longevity and speed as the bit wears a little more, but considering that they are produced by the same parent company, we highly doubt there will be much of a noticeable performance difference.

So What Bits do we Recommend?

We sell several different brands and options for SDS-Plus, SDS-Max and Spline carbide bits for various reasons. Often time, our customers prefer to purchase 2-cutter carbide and full head 4-cutter bits in bulk to accommodate a variety of different jobs and applications. For some applications, they will use a fresh bit, drill a few holes, and who knows when they’ll need it again? For those uses you can just grab the cheapest bit you can find. For other applications where you need to drill hundreds of holes, when the speed and bit life are going to be bigger factors, it makes more sense and in the end saves you money going with a more expensive bit from the start.

The intent for the Ohio Power Tool Selecting Guides is always to help you find the Right Tool for the Job and application. We wanted to touch on all the main features, specs and other factors that will help guide you outside of price and promotions that seem to change constantly. If you ever have specific questions feel free to contact the team at Ohio Power Tool at 800-242-4424 or sales@ohiopowertool.com, or feel free to leave a comment below!