In all of our Right Tool for the Job Guides, we want to cover the background, basic specs and features for that category of tools or accessories to share with you the options available that will make different tools better for different tasks. These are not comparisons, and may likely be a lot of information that you already know, but these are a culmination of conversations we have every day that will hopefully provide some additional considerations for you before making that next purchase decision.

QUICK HISTORY OF CIRCULAR SAWS

The first saws with circular blades can be traced all the way back to the end of the 1700’s and windmill powered sawmills, but they didn’t really take off until steam power was more common in the mid-1800’s. The new buzzing sound that circular saws made compared to the existing up-and-down pit saws gave them the nickname buzz-saws. The hand-held circular saws that we think of today really became popular in 1923, with the invention of the Worm-Drive Saw from a company which later became SkilSaw. In 1928, to get around patents, a direct drive version of the circular saw hit the market from Porter-Cable.

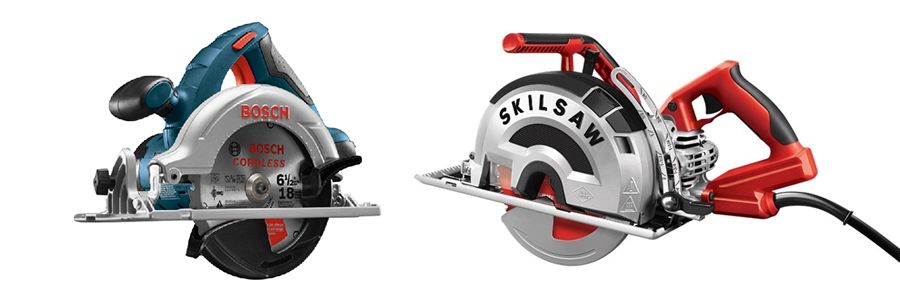

CORDED VS CORDLESS

When it comes to circular saws, there are still many people out there that simply think cordless circ saws could never be equal to corded power. This is likely a common thought because, until very recently, that was the case. Almost all cordless circular saws were much weaker–good for sporadically ripping plywood or cross cutting 2x4s and that’s about it. Today, we absolutely have cordless circular saws for about every major pro brand that can equal and/or exceed the power of corded circular saws. Looking ahead a few years, it’s hard to imagine that the majority of circular saws won’t be cordless.

POWER RATING

So you probably want to know, first and foremost, which saw is most powerful. Of course you do, but unfortunately, there is no torque or power output standard for circular saws. For corded circular saws, AMPs are essentially the standard, but pulling 15 AMPs doesn’t really tell you how powerful a motor is compared to another. Higher AMPs could be more powerful, or just much more inefficient. For cordless circular saws, you don’t even have an AMP rating. Ideally, they would all provide a 3rd party verified average and max watt output, but we don’t have that for most circular saws for now. Unfortunately, you’ll need to rely on manufacturer’s claims of greatness and comparison testing from tool reviewers on Youtube… Seriously, that’s it.

DOES VOLTAGE EQUAL POWER?

There are professional cordless circular saws in 18V, 36V and 54V (60V max*), but higher voltage does NOT actually mean more power. Higher voltage does typically equate to lower current, which is very helpful in dealing with heat–one of the biggest issues with power hungry cordless tools. With new battery cells and better electronics, we now see 18V cordless circular saws that can outperform most 36V or 60V saws, as well as corded circular saws. With good engineering, we’d say voltage is a consideration, but not a limiting factor in the cordless circular saw category, and certainly does not equal more power.

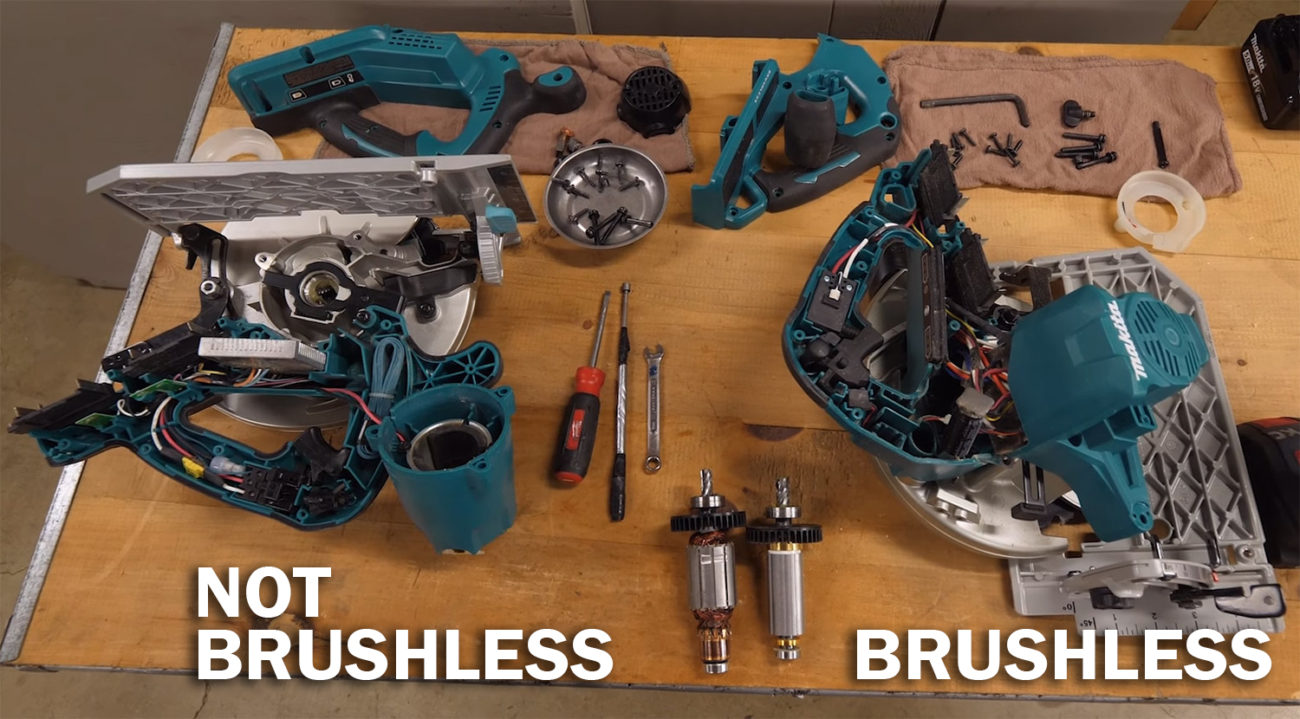

BRUSHED OR BRUSHLESS

A common buzz word you’ll see when comparing circular saws is “brushless”, which has traditionally meant the biggest, most powerful and newest technology. There is much less research going into improving brushed tool motors at this point, but every year we see new surprises with brushless technology. We are also seeing a trend toward using brushless motors in more compact tools, including circular saws, so brushless no longer always means biggest and most powerful. Brushless has become a marketing tool which can be slapped on the side of the box of many tools, so be careful. Yes, the best cordless circular saws will be brushless, but just being brushless doesn’t make them the best.

RPMs

A prominent spec you’ll find on all circular saws are RPMs. Most will fall between 5,000-6,000 RPM, all rated at No Load. Higher No Load RPM tells you very little about power & performance under load, it only speaks to what happens before you actually try to cut anything. This is really more of a complimentary spec. Once you know what sort of power output you have, running a higher RPM should mean it’s backed by more power. However, manufacturers can easily get the RPM number without actually adding any power, which will in turn just make the tool less efficient.

WORM-DRIVE / REAR-HANDLE

As mentioned above, worm-drive were the original hand-held circular saws. Adding the gear gives more power and creates a natural soft start, but on the other hand, means that they are larger, heavier, and often more costly. Cordless “rear-handle” circular saws are built to imitate the look and feel of worm-drive corded circular saws. These units are larger and heavier, putting the handle behind the motor and switching the blade to the left side. While there are several manufacturers with rear-handle cordless circular saws, the only brand that actually uses the worm-drive mechanics in their cordless saw is SkilSaw. For those that prefer the blade left and rear-handle setup, these give the same feel and are some of the most powerful options available.

BLADE LEFT OR RIGHT

Which is best? These are not saws created exclusively for left-handed or right-handed people, but are more commonly a preference based on where you live in the country or what your dad had sort of thing. Most pro brands of cordless tools have options for left or right blade saws, but typically these are different types of saws (rear handle, metal cutting, or compact). We’re never going to get everyone to agree, so it’s best to just go with what feels right for you.

BLADE SIZE: 7-1/4” or 6-1/2” or 5-3/8”

The traditional circular saw blade size is 7-1/4”. This size is still the most common and readily available with the most options–anything from high precision blades to rough cut, metal cutting, specialty flooring and much more. Today, the most powerful cordless circular saws are all using 7-1/4” blades, which for the most part are intended for heavy-duty use and match corded saws in power. They also give the most capacity, around 2-1/2” to 2-5/8” depth at 90 degrees.

The 6-1/2” blade has become more popular for cordless circular saws. Since previously the cordless motors were simply not that powerful, they reduced the blade size to limit capacity and give a feel closer to corded. This size continues to go strong as a less expensive option, and these compact circular saws still achieve 2″ to 2-1/4” capacity.

The 3rd most popular size is 5-3/8”, which has become more widely used for metal cutting cordless circular saws, but there are some saws using this size for wood cutting as well.

For high capacity corded circular saws, 10-1/4” or even 16-5/16” with over 6” capacity are an option. Will we see these massive saws go cordless in 2020 or 2021? For sure we will. There is no official word yet from any brands, but why would they not? These saws have a lot of application far away from an outlet and would be very welcome additions to any cordless platform.

COMPACT CIRCULAR SAWS

We are seeing more Compact and Sub-Compact cordless circular saws hitting the market, which are intended primarily for professional use. These are not going to replace your full size 7-1/4” for a heavy user as your primary circular saw, but for home owners, these will do fine as an only option. We’ve found many pros using these as a secondary tool for a lightweight option when working at heights, overhead applications, or quick jobs. These are intended to decrease the tool size without sacrificing too much on power, and if you do buy one with that in mind, you’ll likely find yourself using it more than you thought.

METAL CUTTING CIRCULAR SAWS

Do you need a dedicated metal cutting circular saw for cutting lots of aluminum studs, conduit, strut, rod, pipe, etc. on a daily basis? There are metal circular saws available with 5-3/8” & 8″ cordless or corded that are only intended for metal cutting. With a lower RPM and the ability to handle hot metal chips, these are really intended to replace band saws or grinders more so than traditional circular saws. With newer blade technology, you certainly can get metal cutting blades that allow metal cutting for occasional use with a traditional, higher RPM circular saw, but a dedicated tool is the way to go for serious metal cutting.

BELLS & WHISTLES

There are of course a ton of other bells and whistles that can be included on circular saws. We think that all new saws should include a rafter hook, LED light, tool free adjustments, blade change hex onboard, and dust collection port attachment, but since they don’t, these are good features to look for when considering the right tool for your job.

The intent for the Ohio Power Tool Selecting Guides is always to help you find the right tool for your job and application. We wanted to touch on all the main features, specs and other factors that will help guide you outside of price and promotions that seem to change constantly. If you ever have specific questions feel free to contact the team at Ohio Power Tool at 800-242-4424 or sales@ohiopowertool.com, or feel free to leave a comment below!